- Messages

- 17,703

- Location

- Maryland

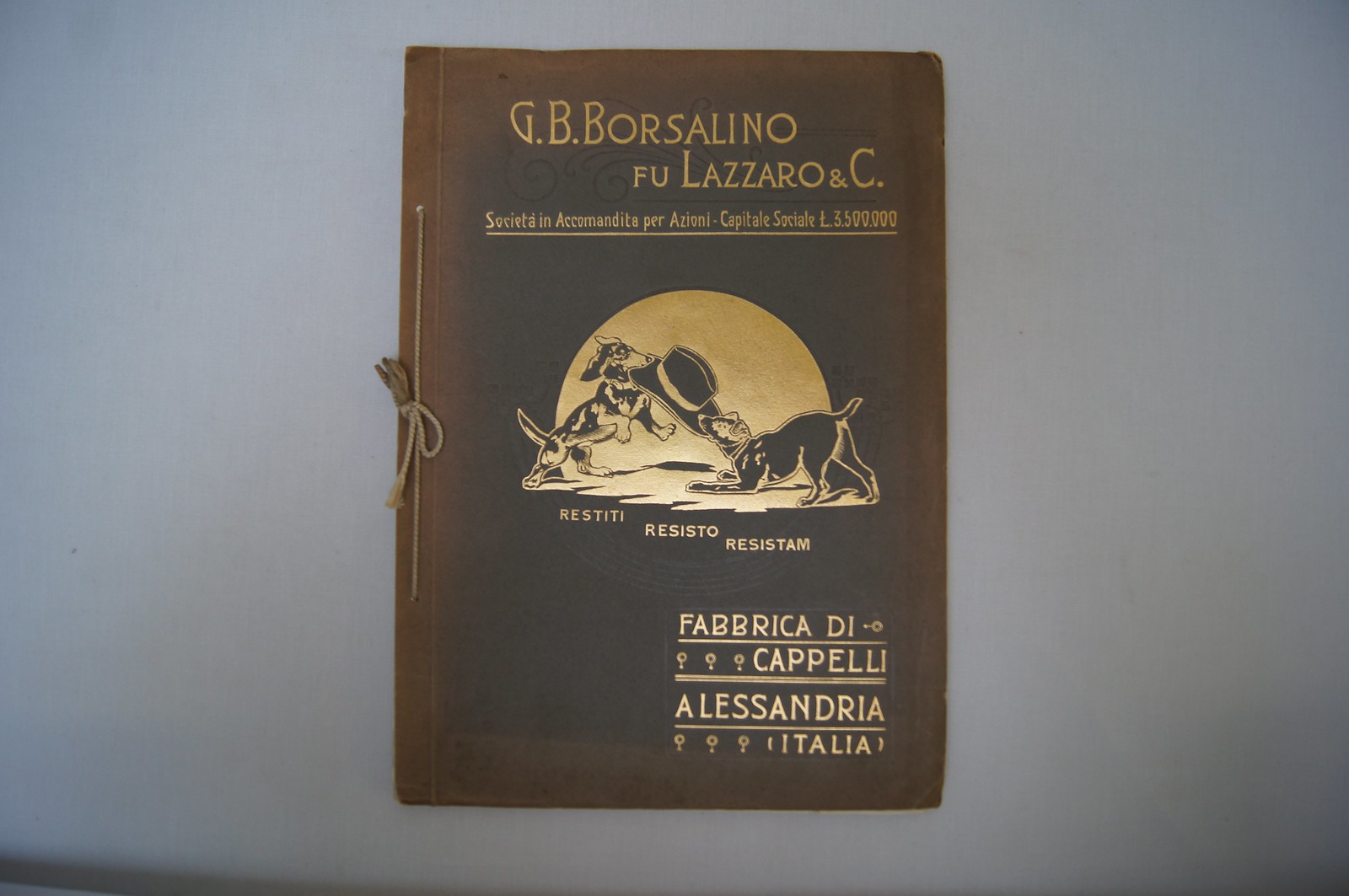

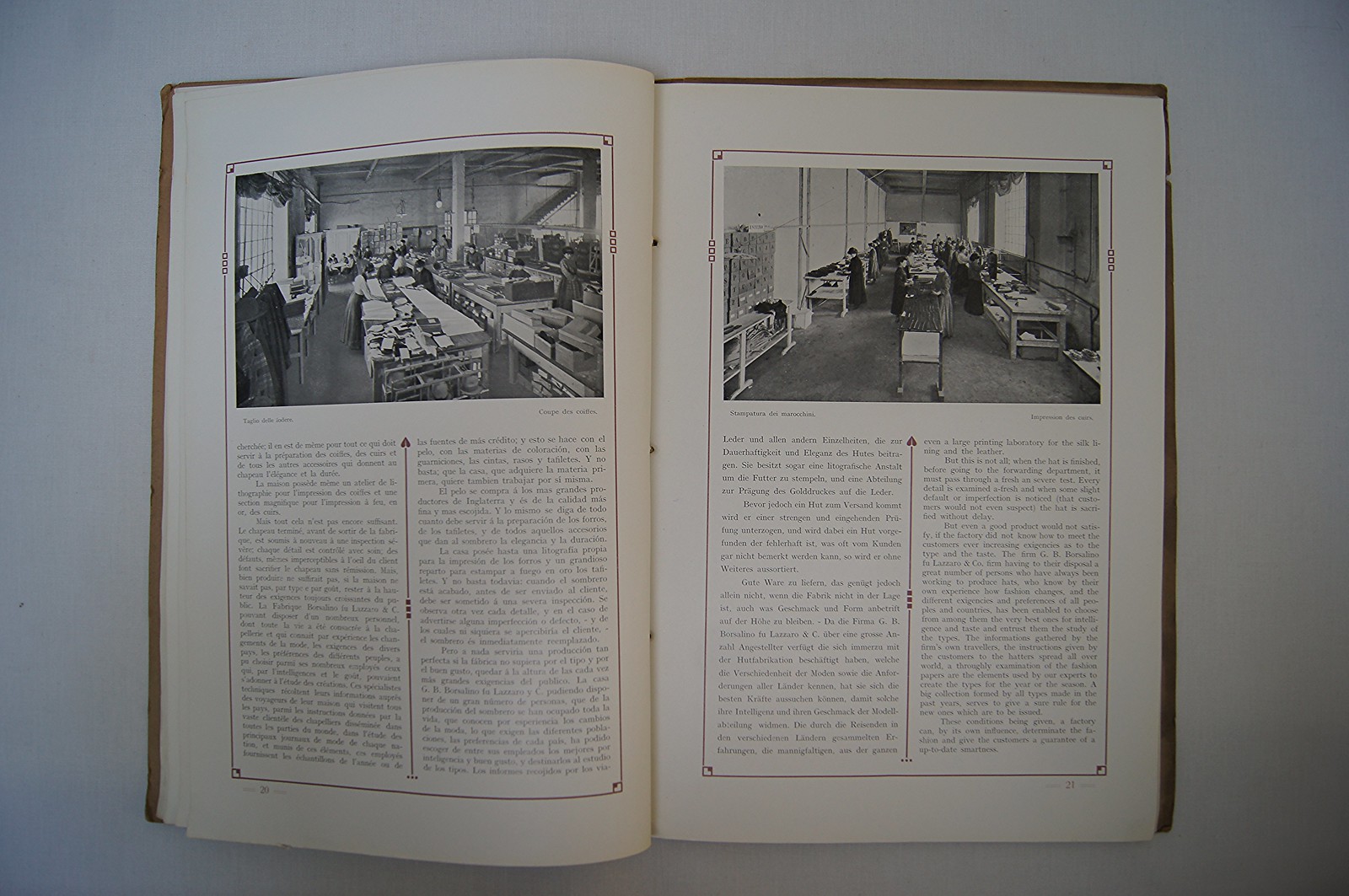

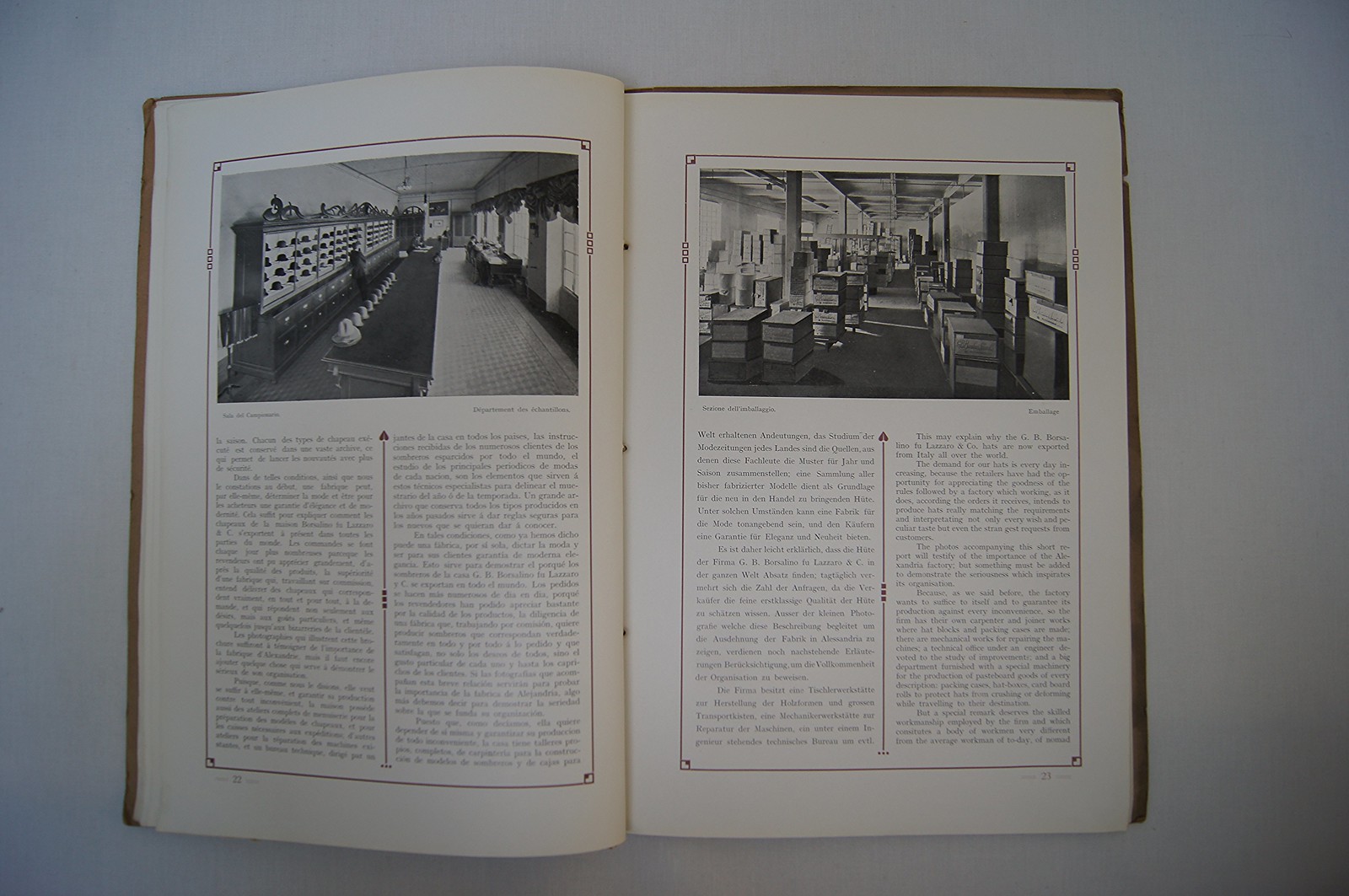

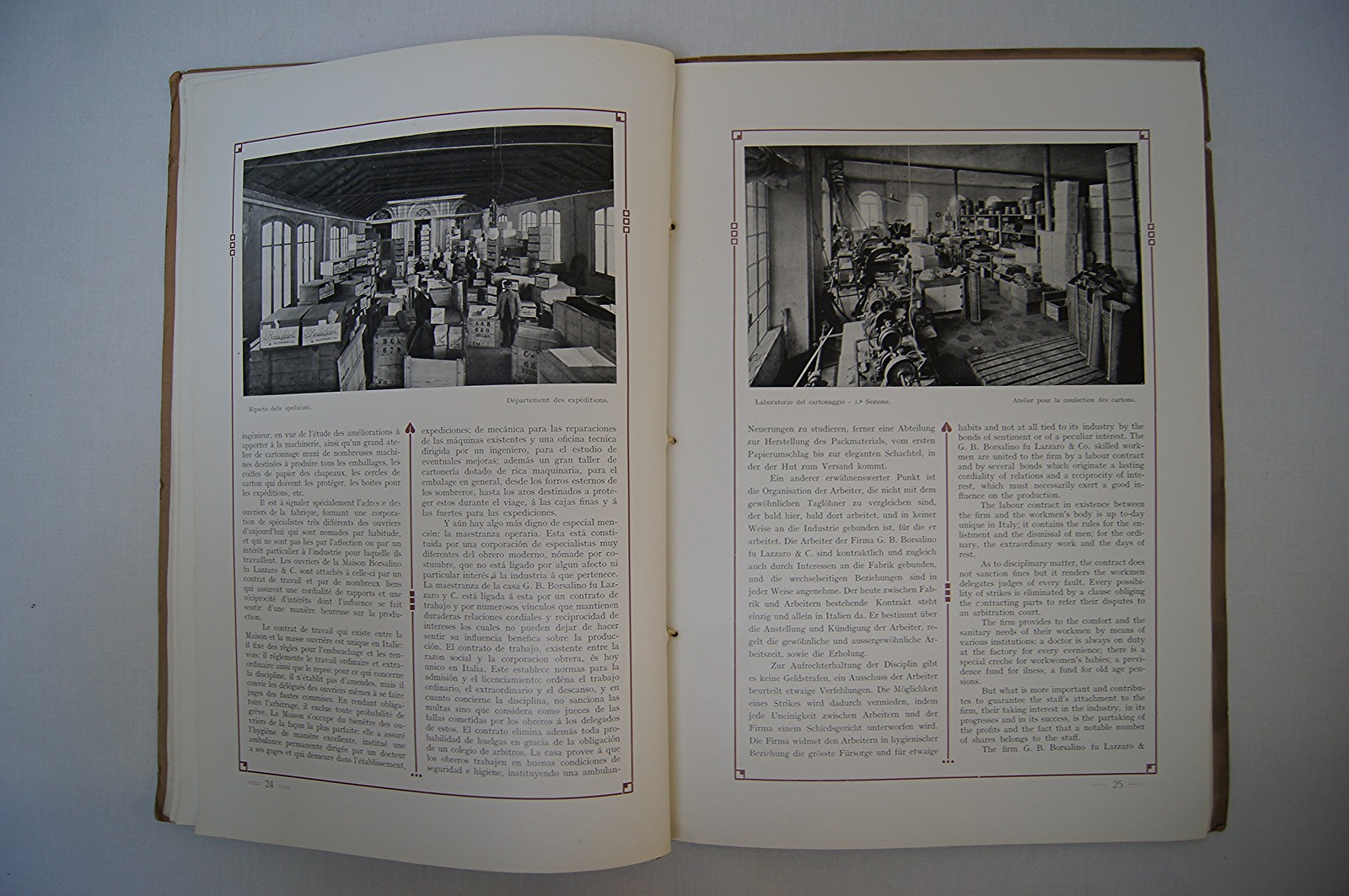

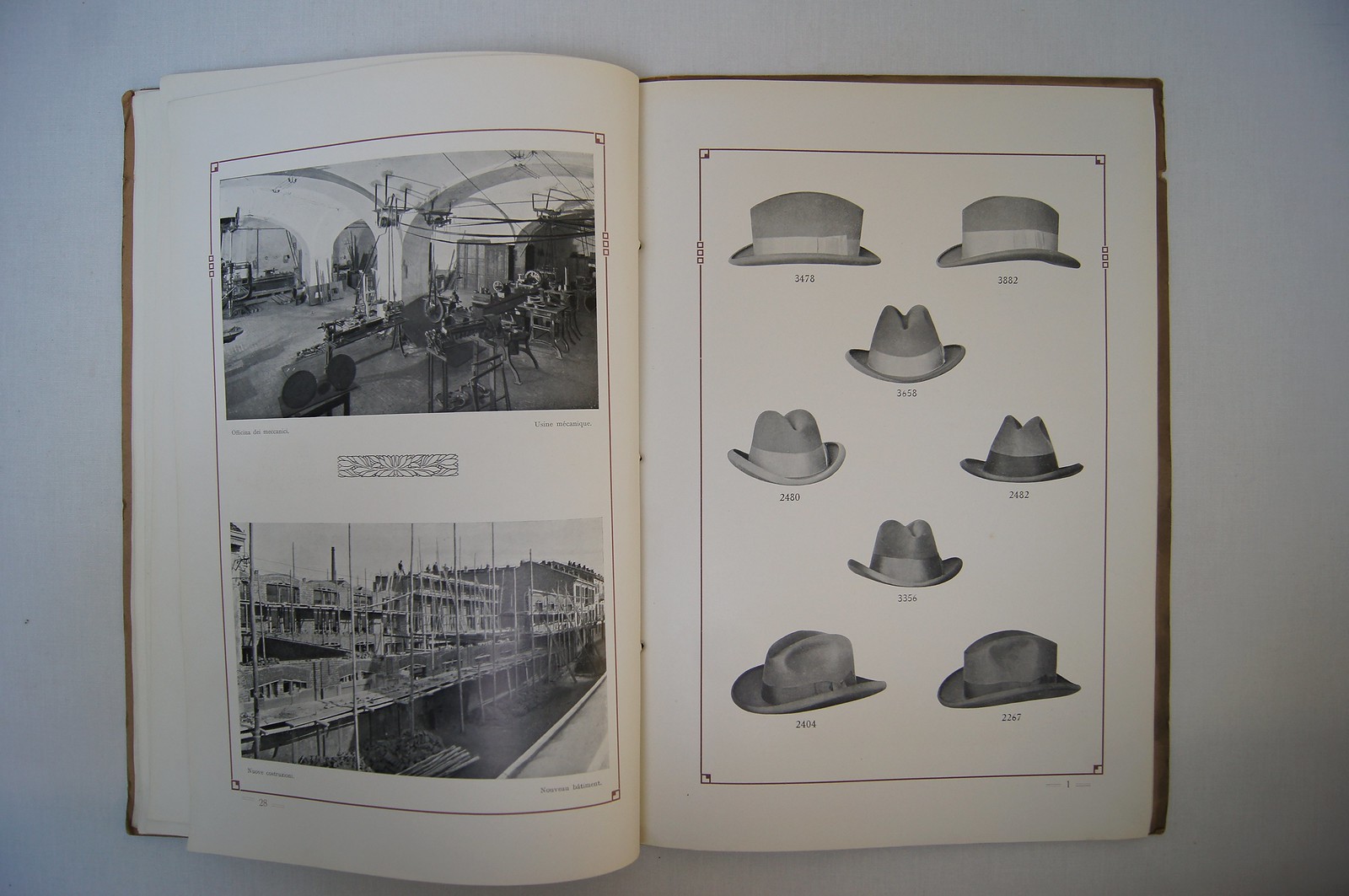

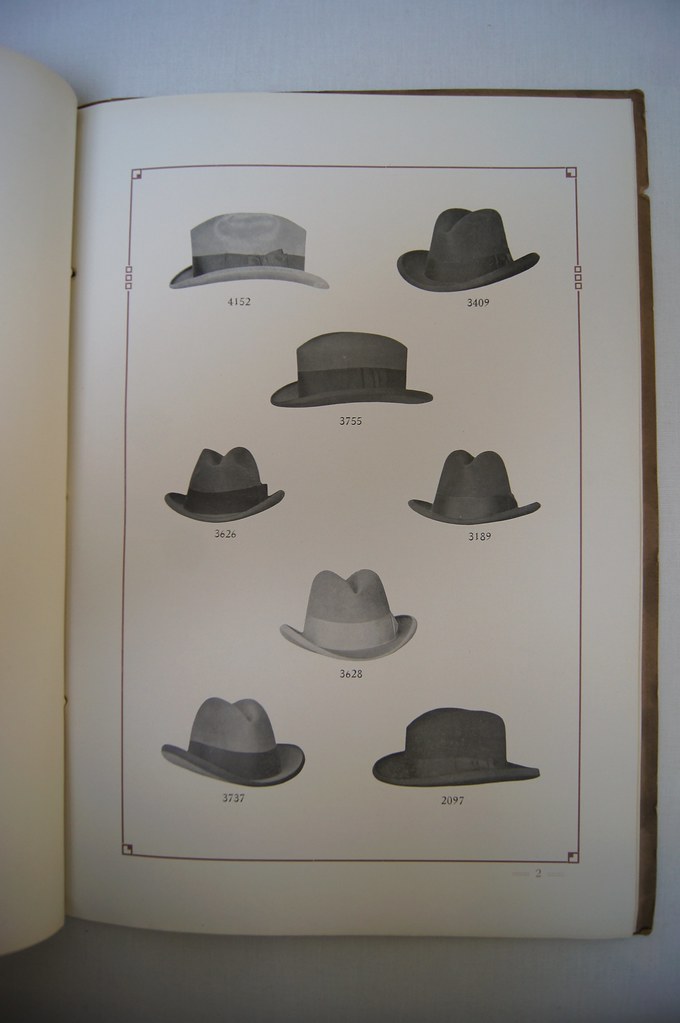

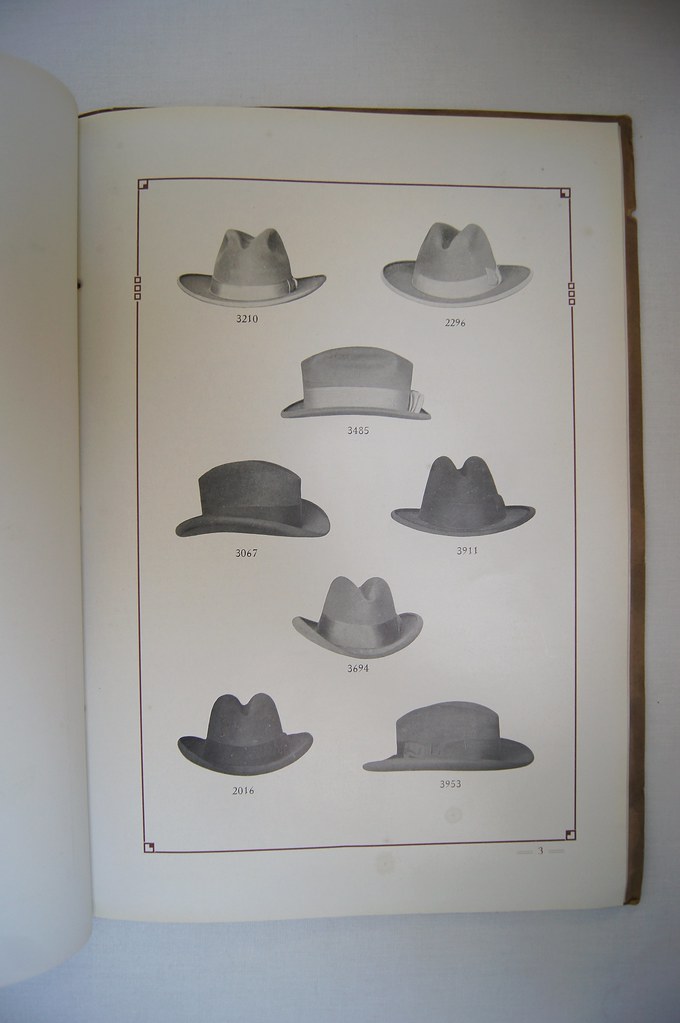

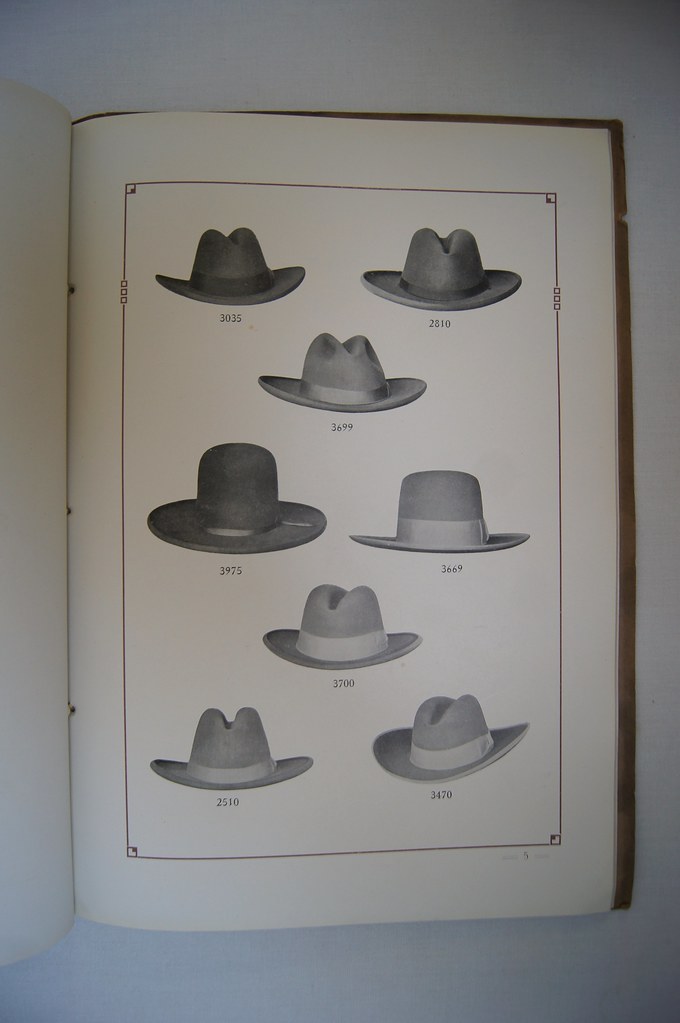

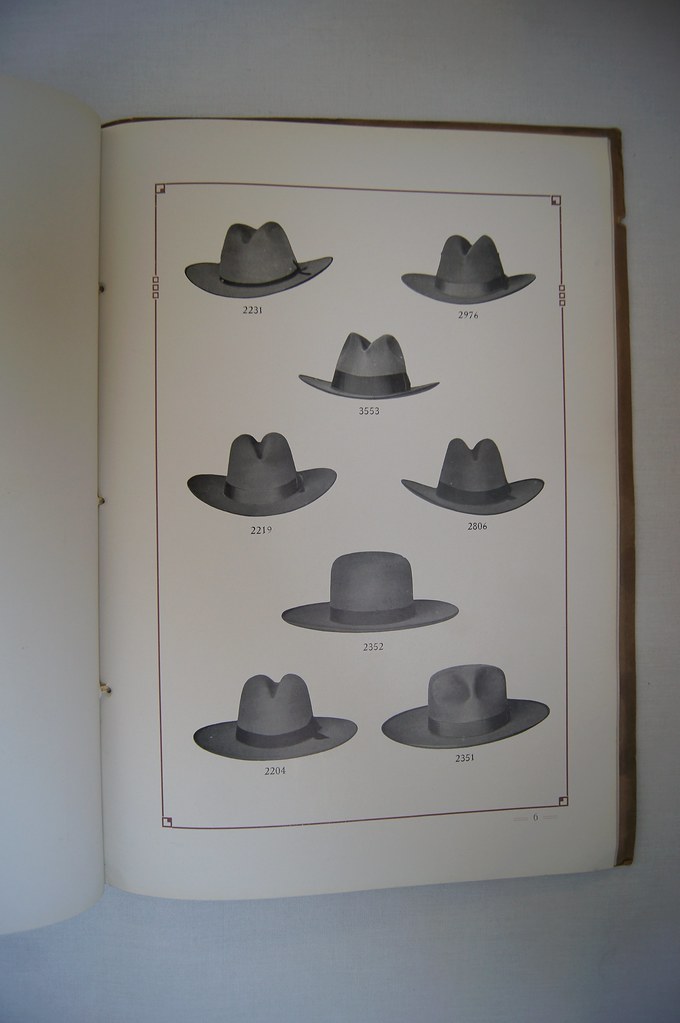

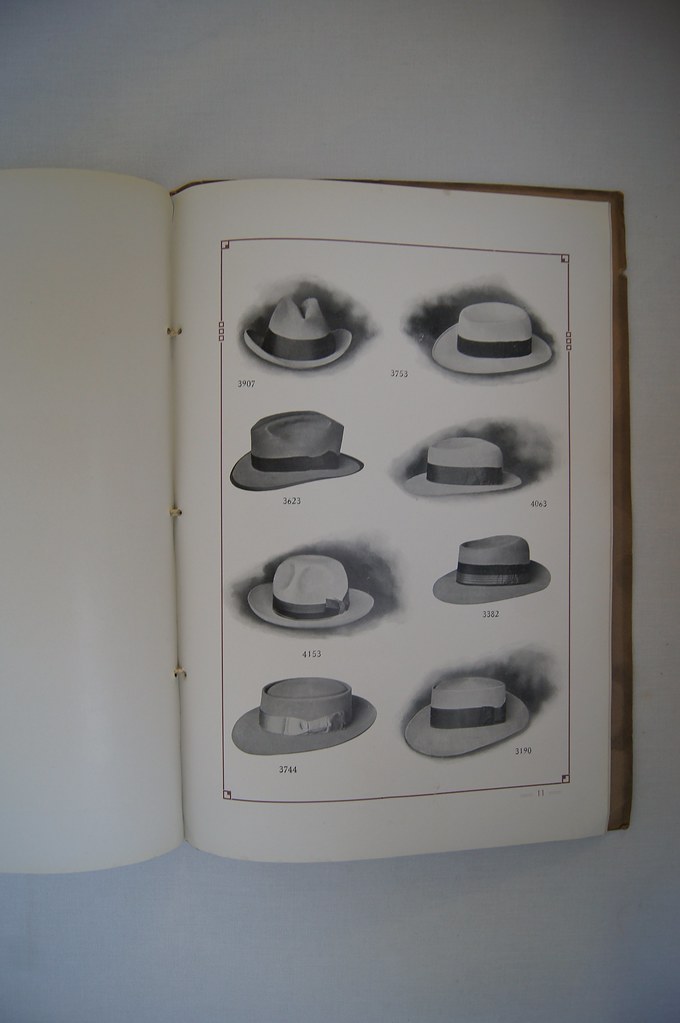

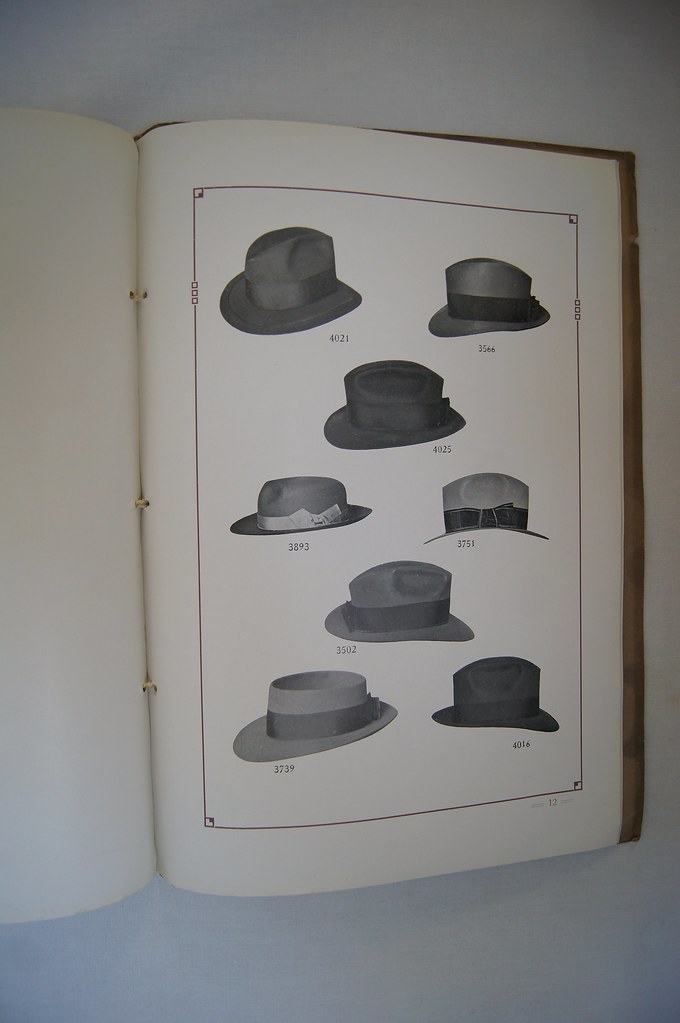

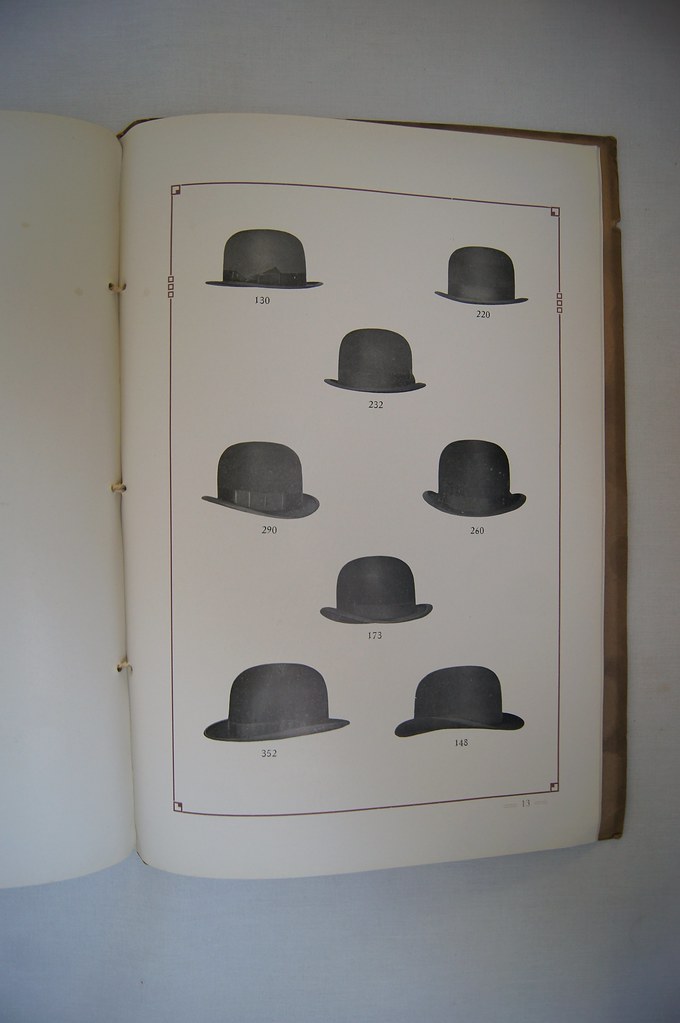

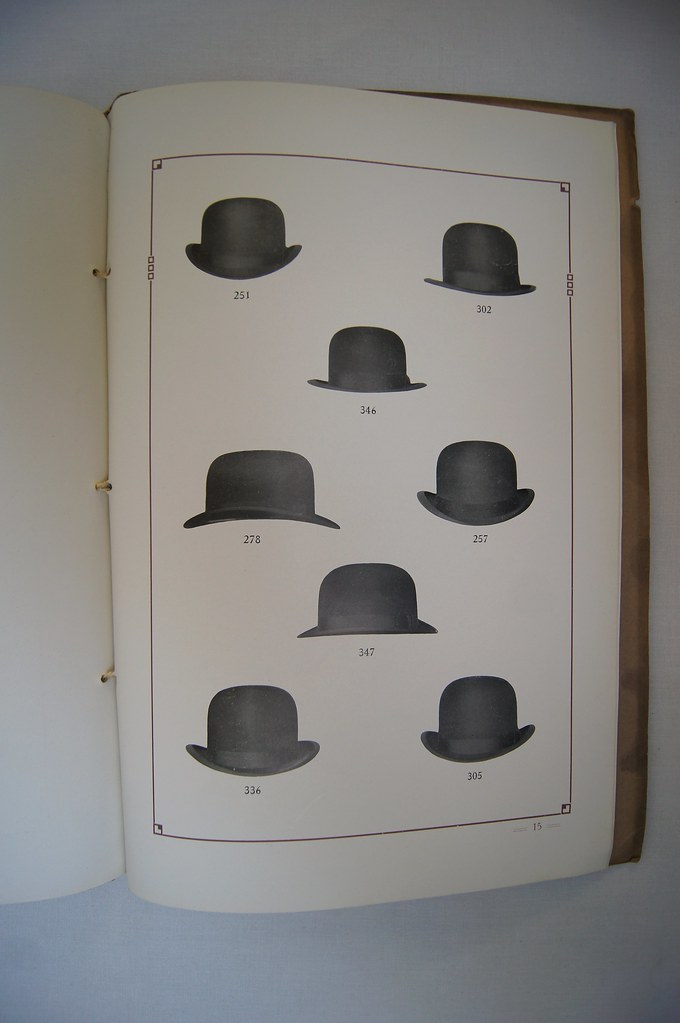

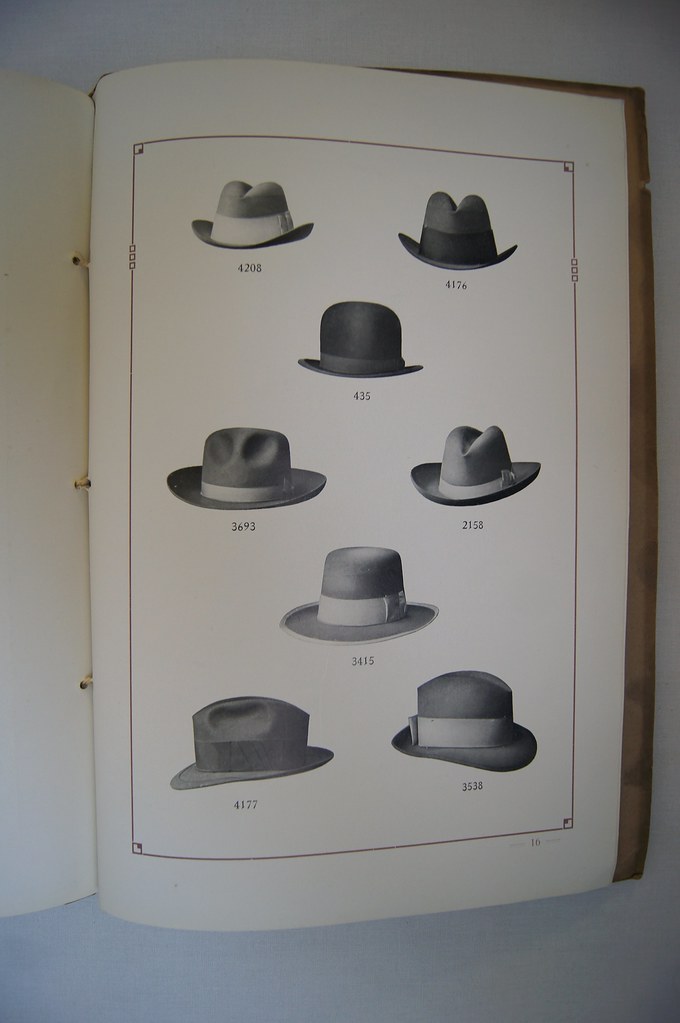

G.B.Borsalino Fu Lazzaro & C. prospectus (Italian, French, English, German, Spanish) from the Gotisches Haus (Gothic House) Bad Homburg , Germany collection, very early 1900s, very late 1800s. This is a long post but definitely worth taking a look at. Click on photos to expand.

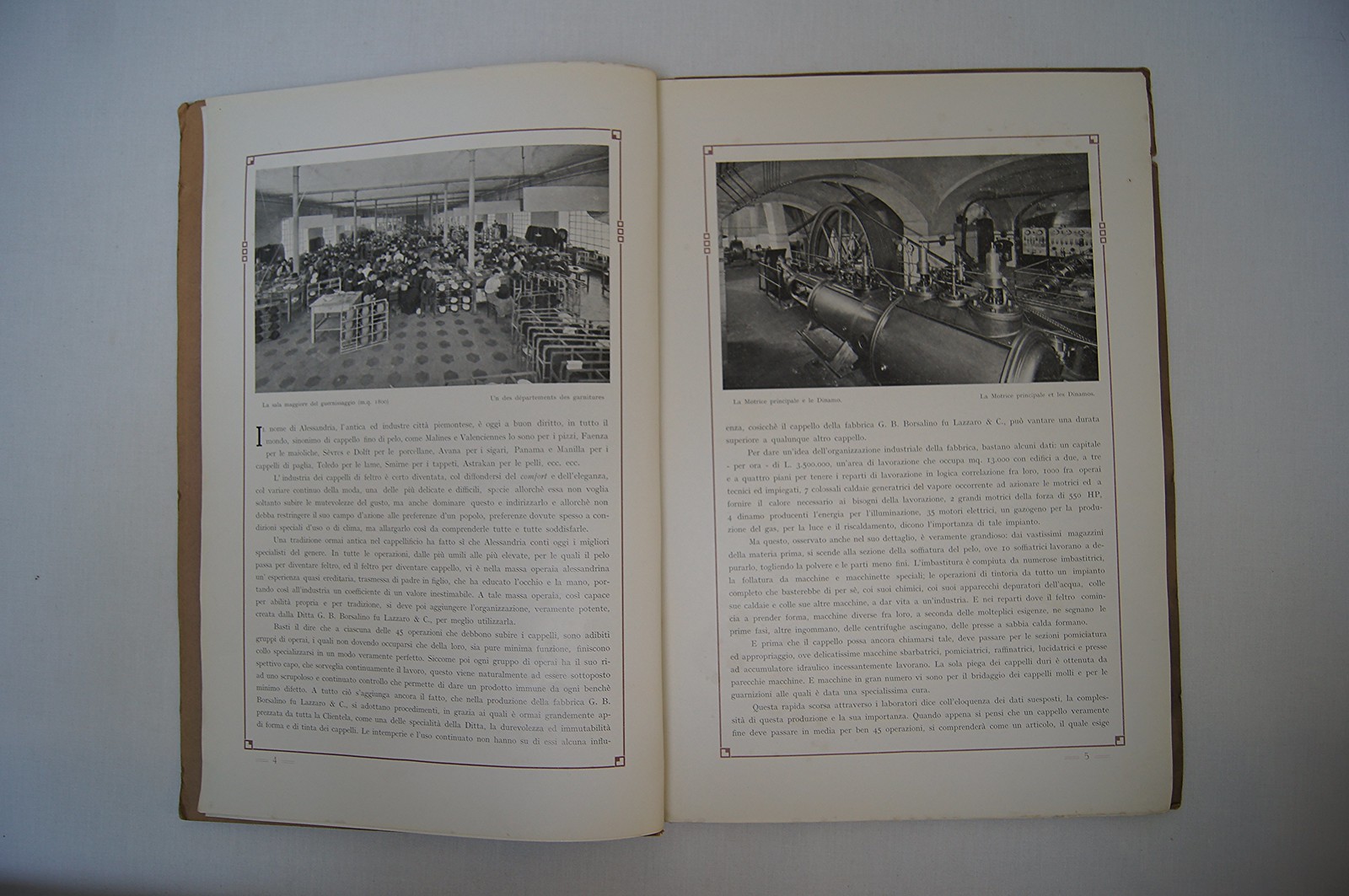

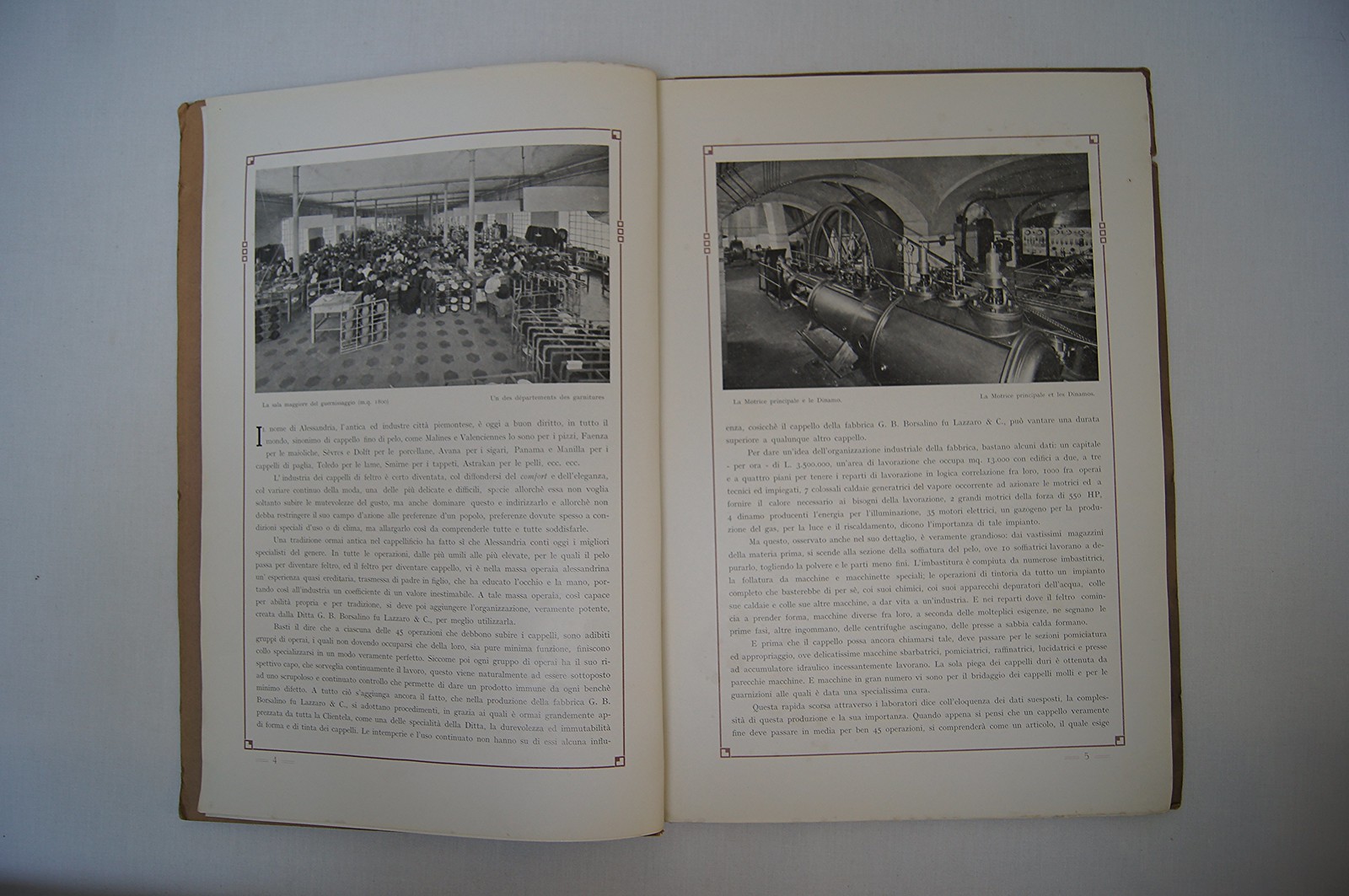

(left) Trim Department (1896?) (right) Dynamo

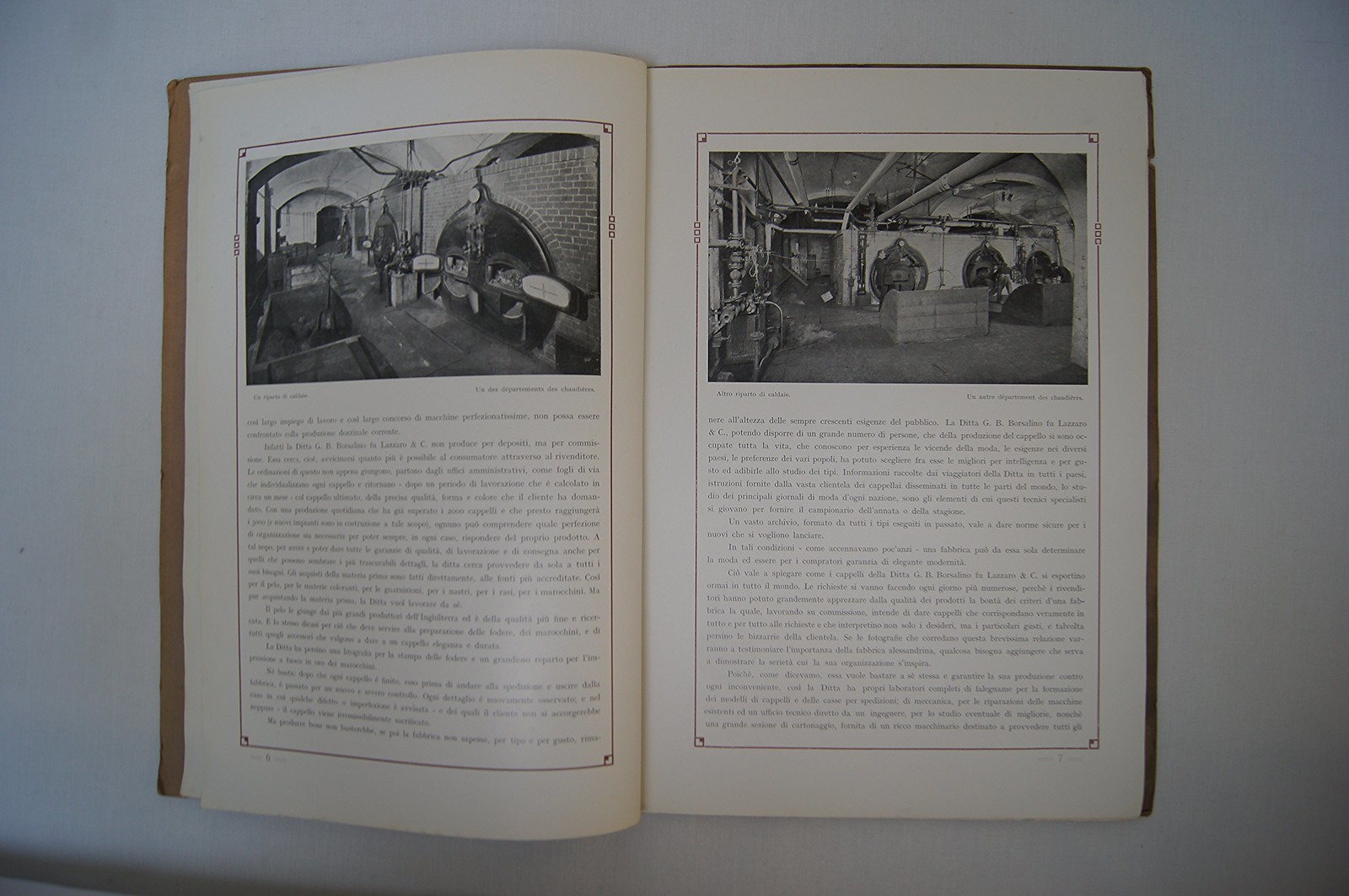

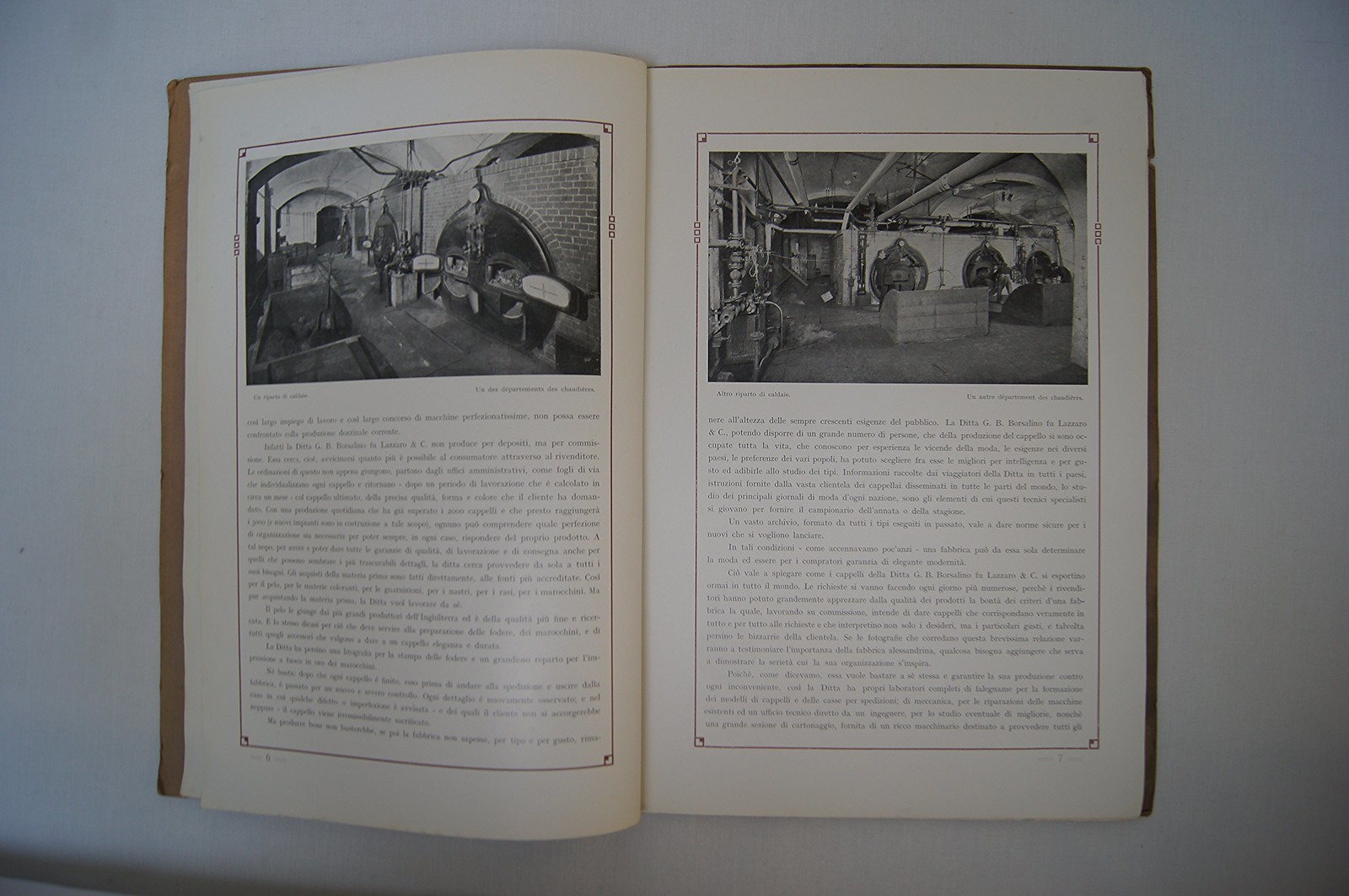

(left) Boilers (right) Boilers

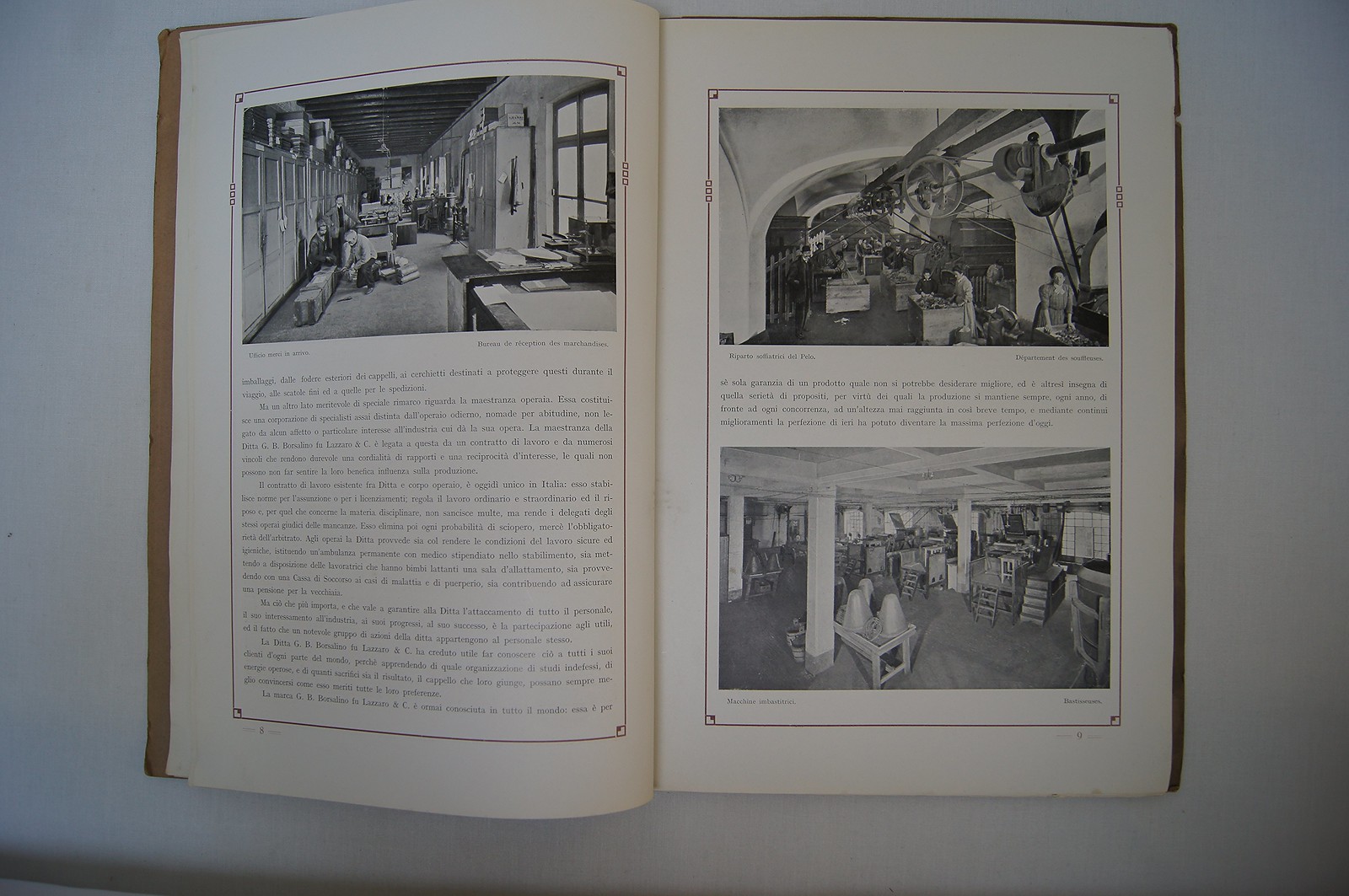

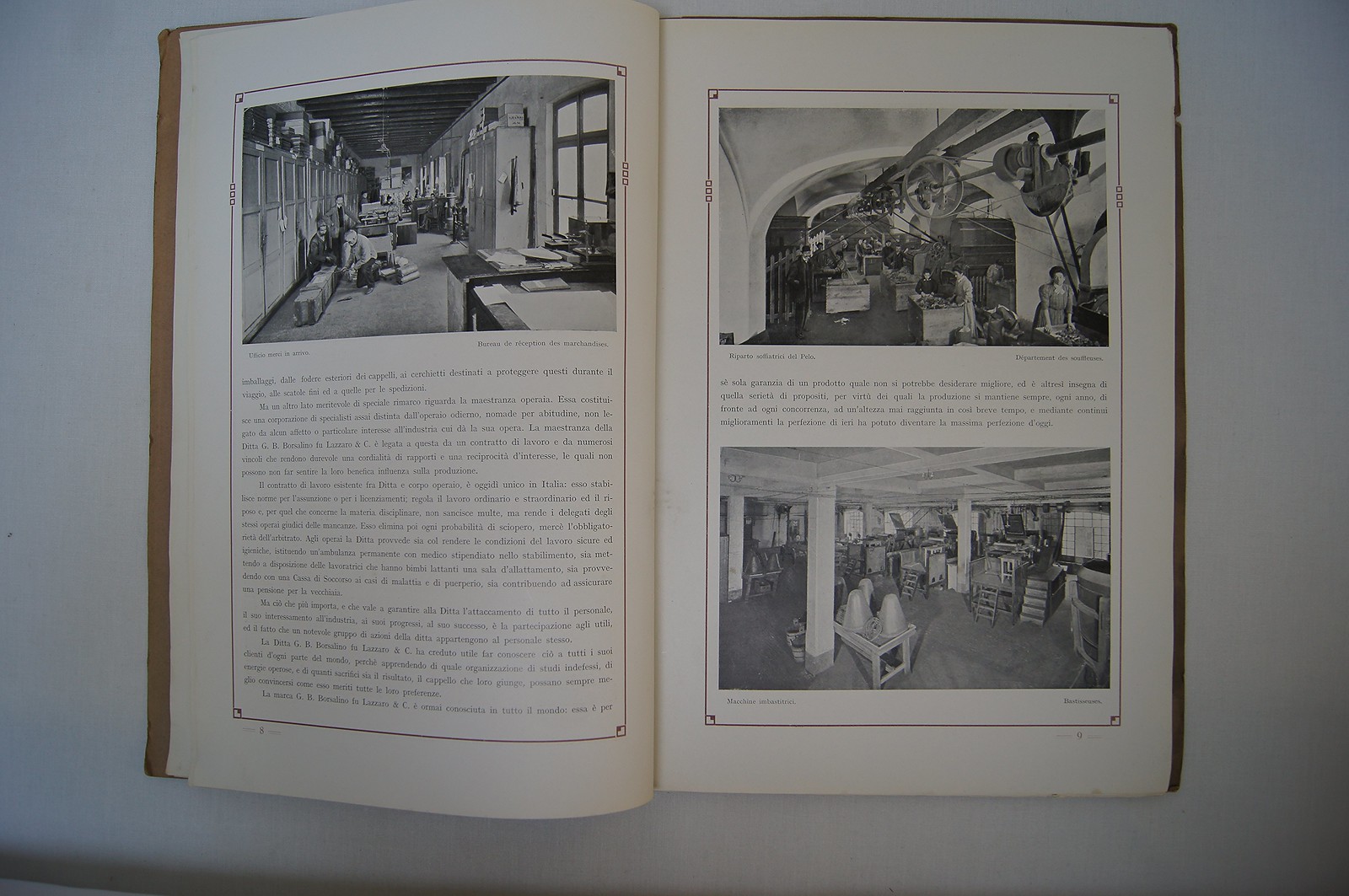

(left) Receivables (right top) Hair Sorting (right bottom) Cone Forming

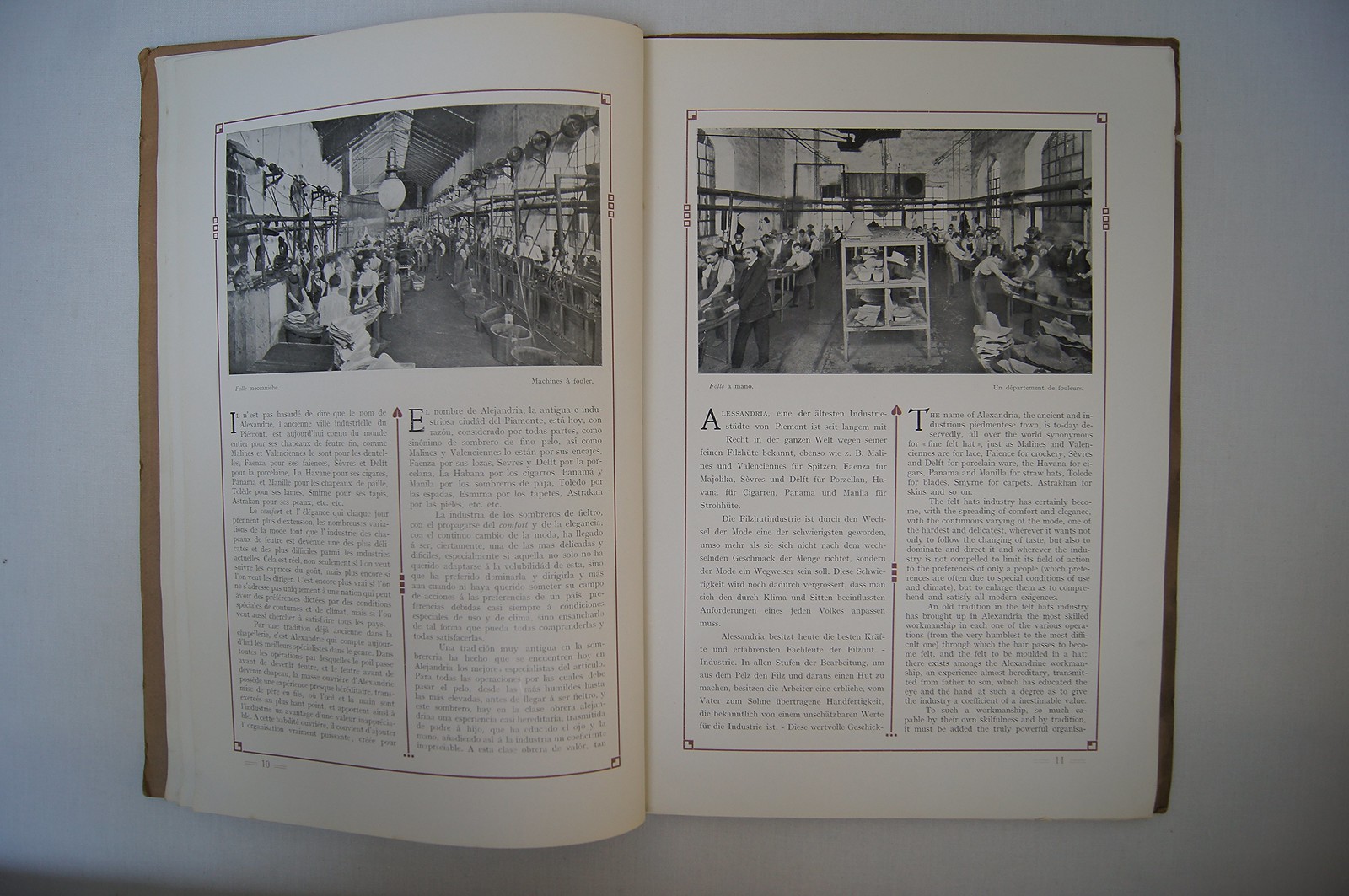

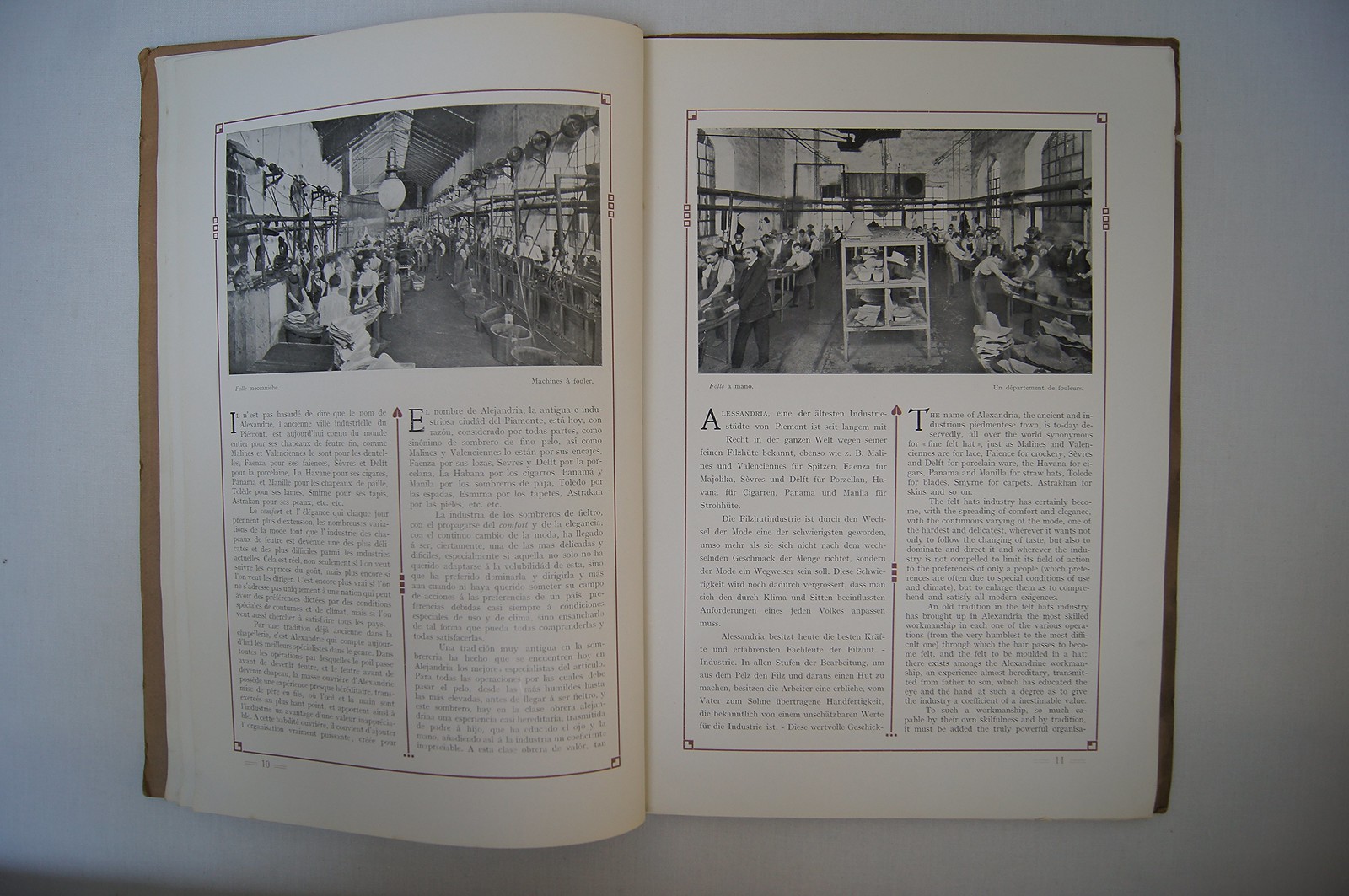

(left) Mechanical Fulling (right) Manual Fulling

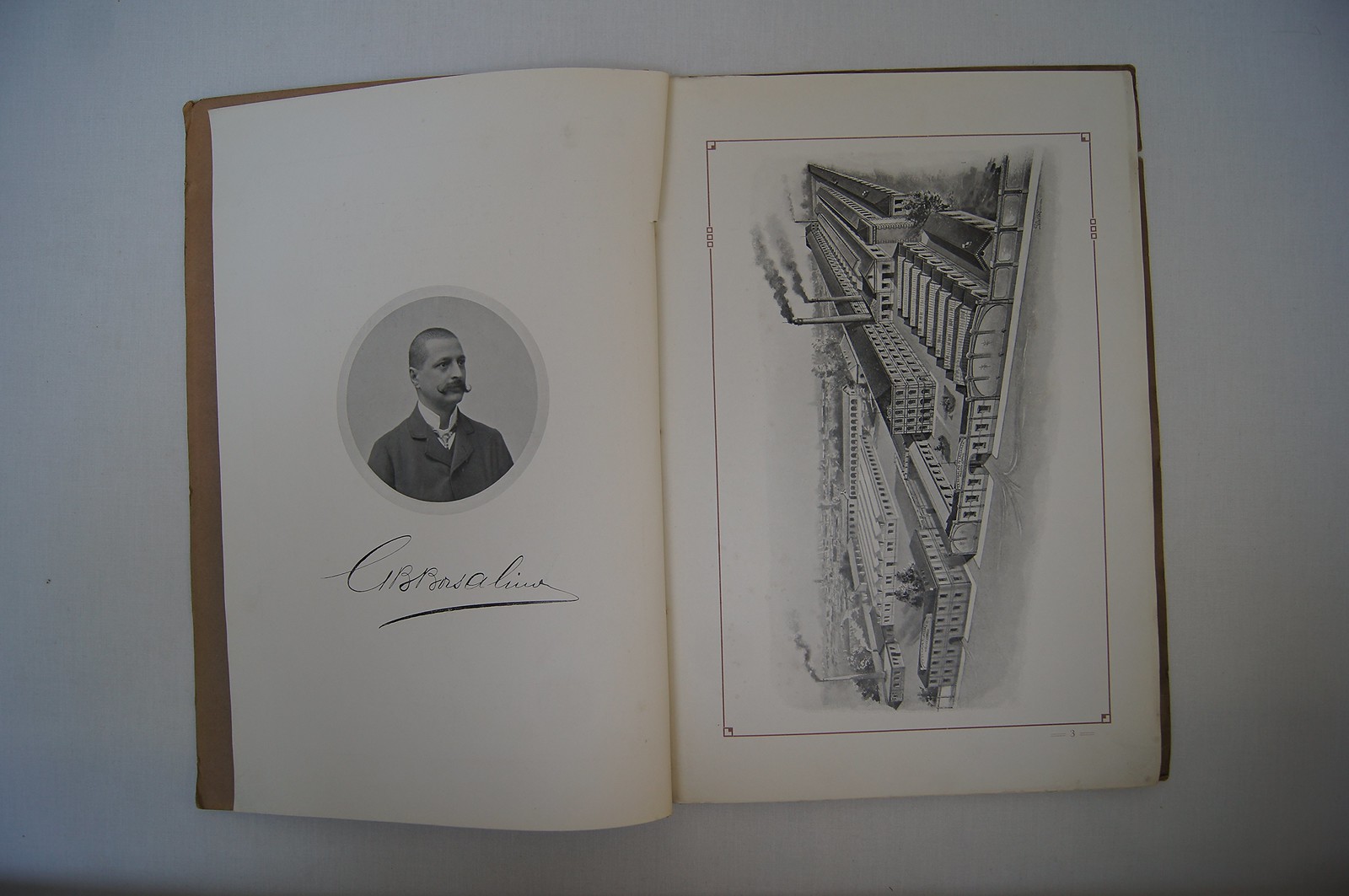

THE name of Alexandria. the ancient and industrious piedmentese town. is today deservedly. all over the world synonymous for ,,, fine felt hat ,, just as Malines and Valenciennes are for lace. Faience for crockery. Sevres and Delft for porcelain-ware. the Havana for cigars. Panama and Manilla for straw hats, Tolede for blades, Smyrne for carpets. Astrakhan for skins and so on.

The felt hats industry has certainly become. with the spreading of comfort and elegance, with the continuous varying of the mode, one of the hardest and delicatest, wherever it wants not only to follow the changing of taste, but also to dominate and direct it and wherever the industry is not compelled to limit its field of action to the preferences of only a people (which preferences are often due to special conditions of use and climate), but to enlarge them as to comprehend and satisfy all modern exigences.

An old tradition in the felt hats industry has brought up in Alexandria the most skilled workmanship in each one of the various operations (from the very humblest to the most difficult one) through which the hair passes to become felt, and the felt to be molded in a hat: there exists among the Alexandrine workman-ship, an experience almost hereditary. transmit-ted from father to son, which has educated the eye and the hand at such a degree as to give the industry a coefficient of a inestimable value.

To such a workmanship, so much capable h their own skillfulness and by tradition, it must be added the truly powerful organic-

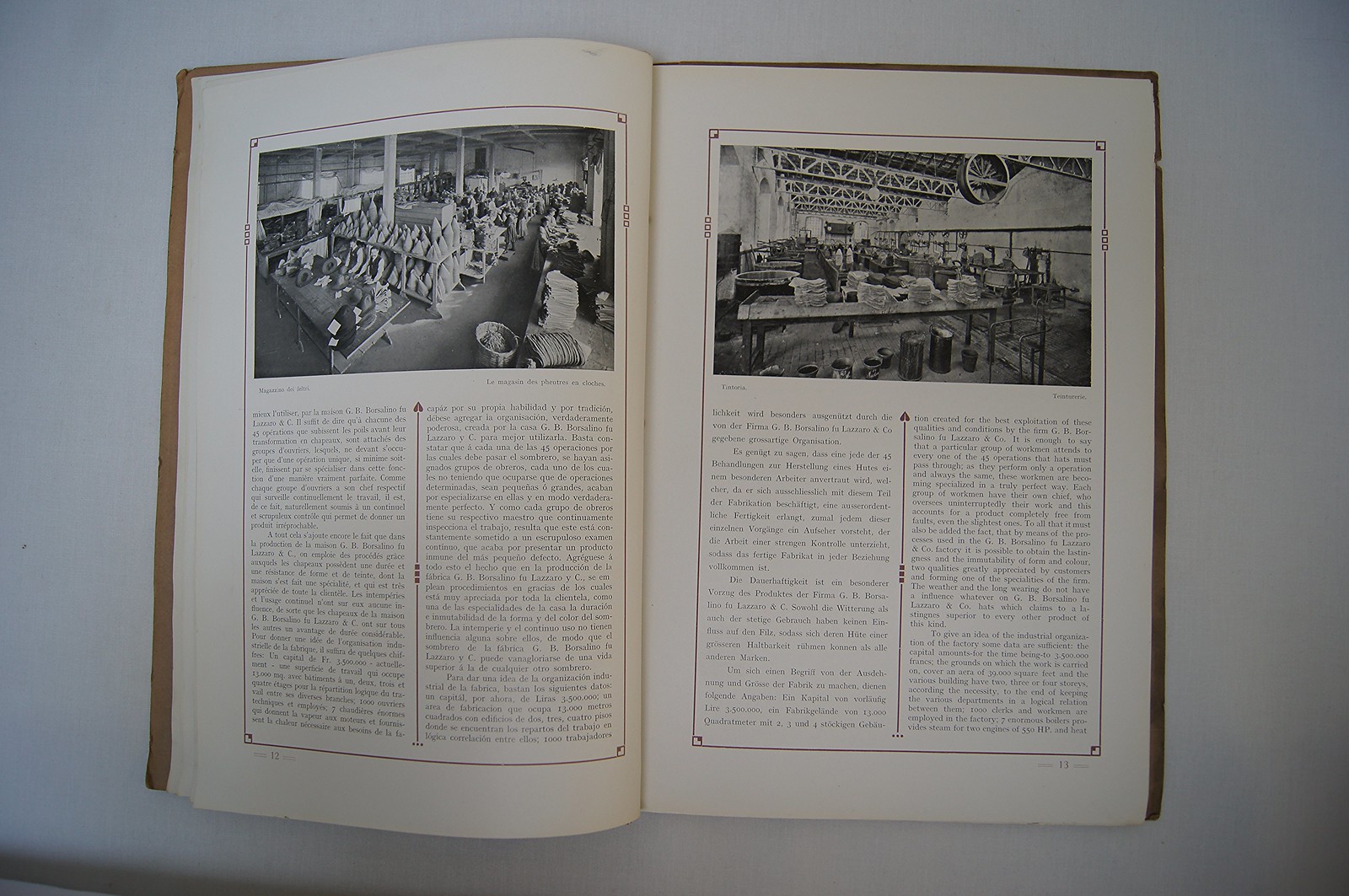

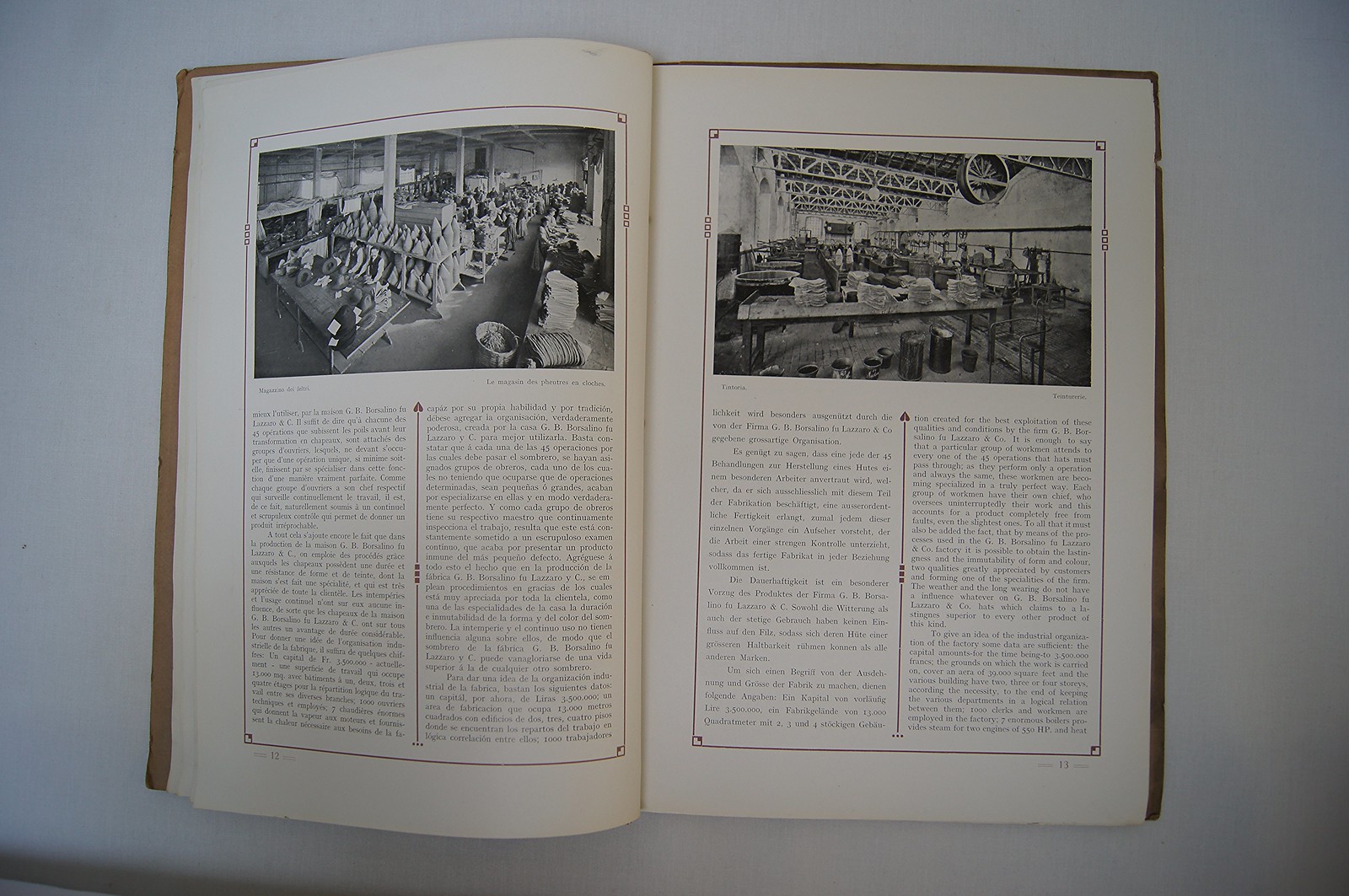

(left) Felt Warehouse (right) Dyeing Department

tion created for the best exploitation of these qualities and conditions by the firm G. B. Borsalino fu Lazzaro & Co. It is enough to say that a particular group of workmen attends to every one of the 45 operations that hats must pass through; as they perform only a operation and always the same, these workmen are beco-ming specialized in a truly perfect way. Each group of workmen have their own chief. who oversees uninterruptedly their work and this accounts for a product completely free from faults, even the slightest ones. To all that it must also be added the fact, that by means of the processes used in the G. B. Borsalino fu Lazzaro & Co. factory it is possible to obtain the lastingness and the immutability of form and colour. two qualities greatly appreciated by customers and forming one of the specialties of the firm. The weather and the long wearing do not have a influence whatever on G. B. Borsalino fu Lazzaro & Co. hats which claims to a lastingness superior to every other product of this kind.

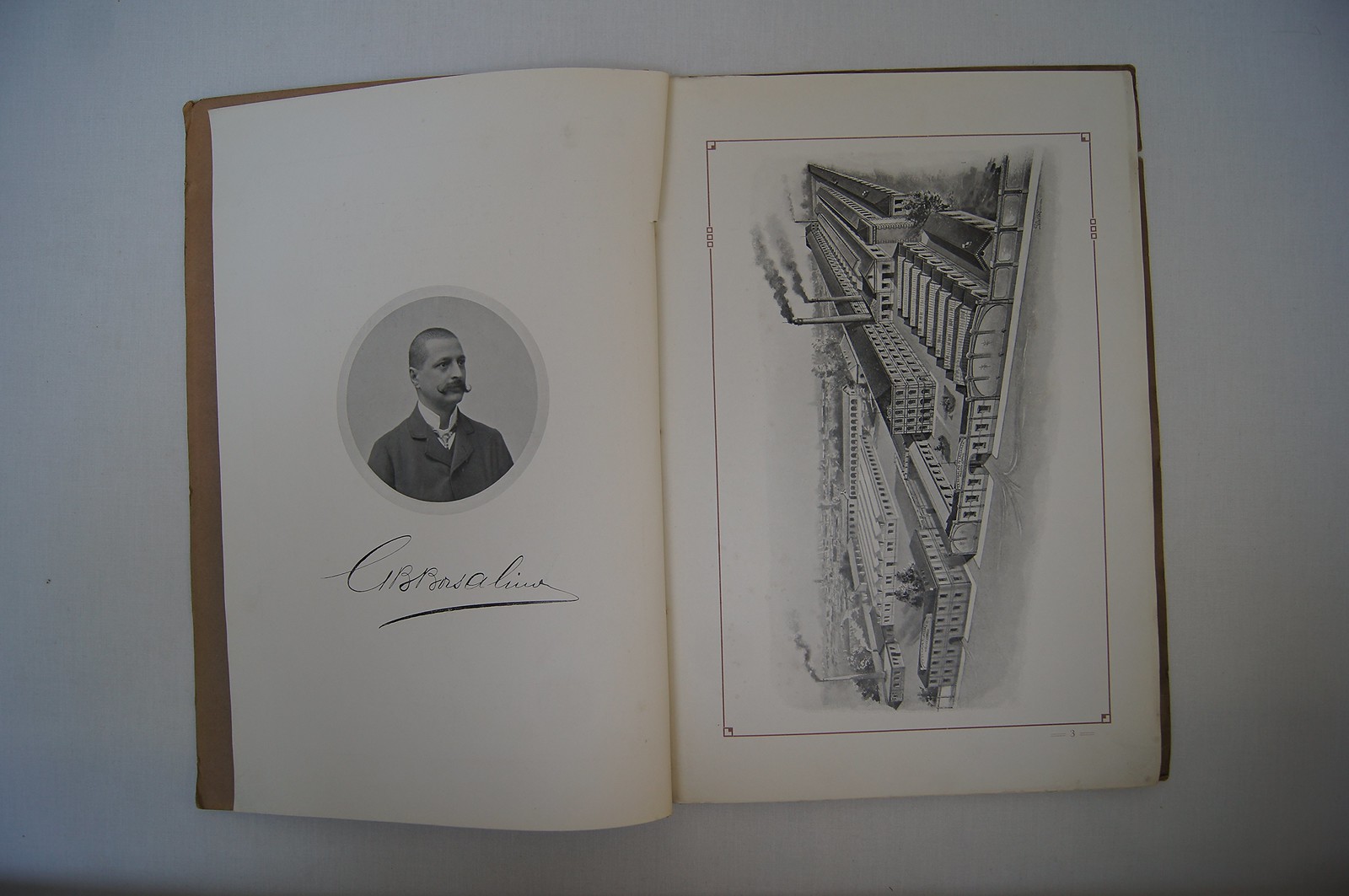

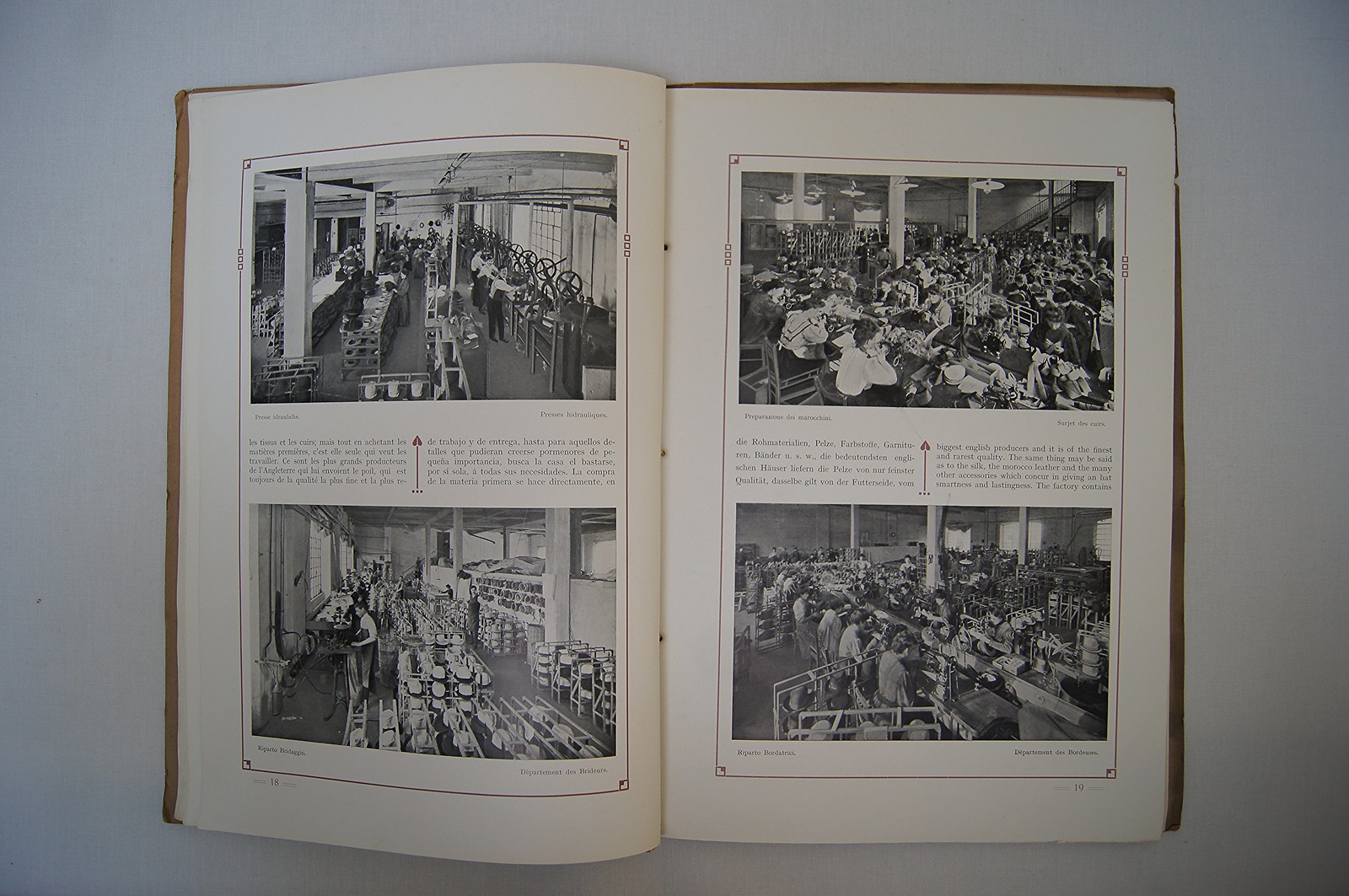

To give an idea of the industrial organization of the factory some data are sufficient: the capital amounts-tor the time being-to 3.500.000 francs: the grounds on which the work is carried on, cover an area of 39.000 square feet and the various building have two, three or four stories. according the necessity, to the end of keeping the various departments in a logical relation between them: tow clerks and workmen are employed in the factory: 7 enormous boilers provides steam for two engines of 550 HP

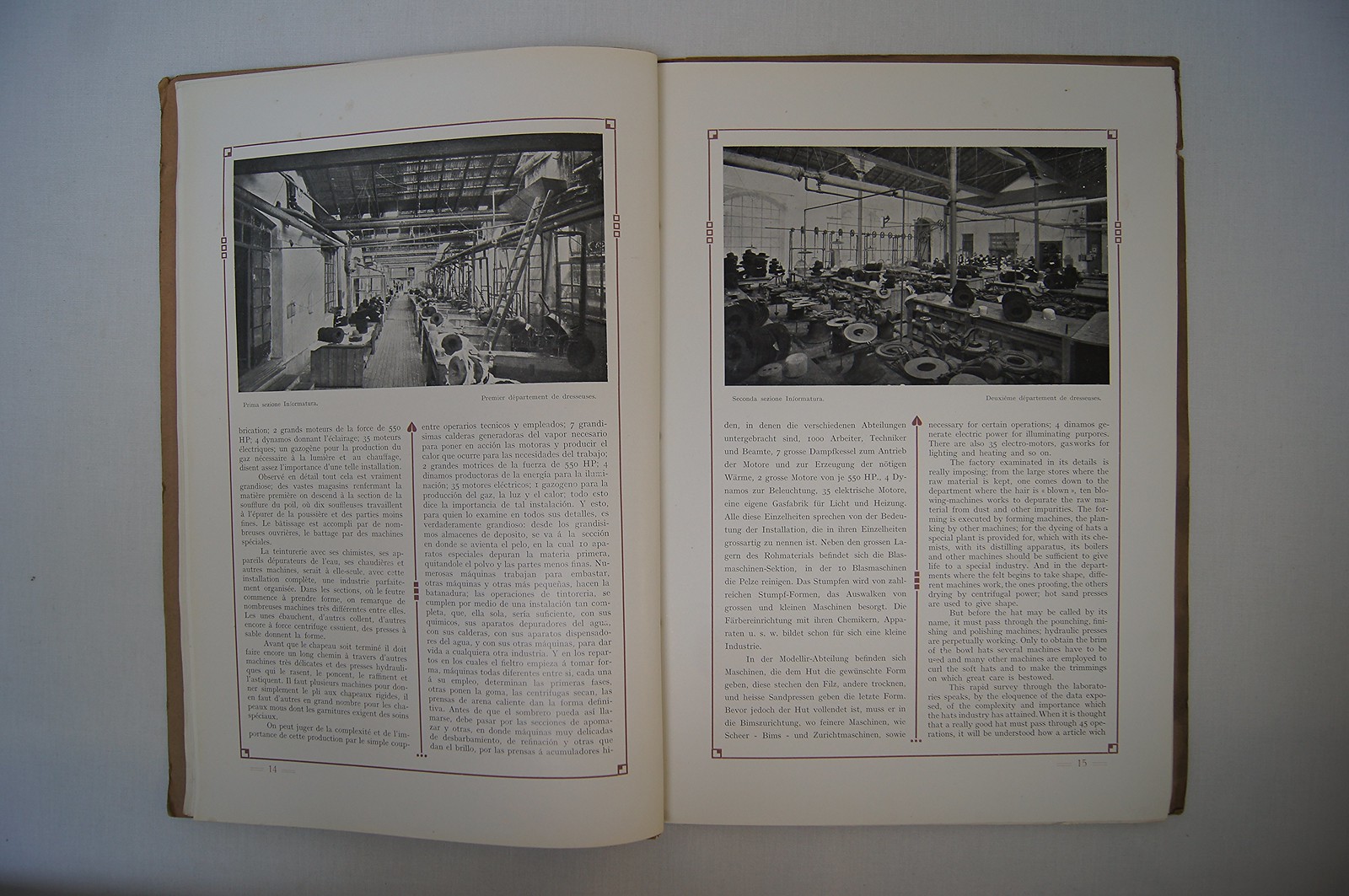

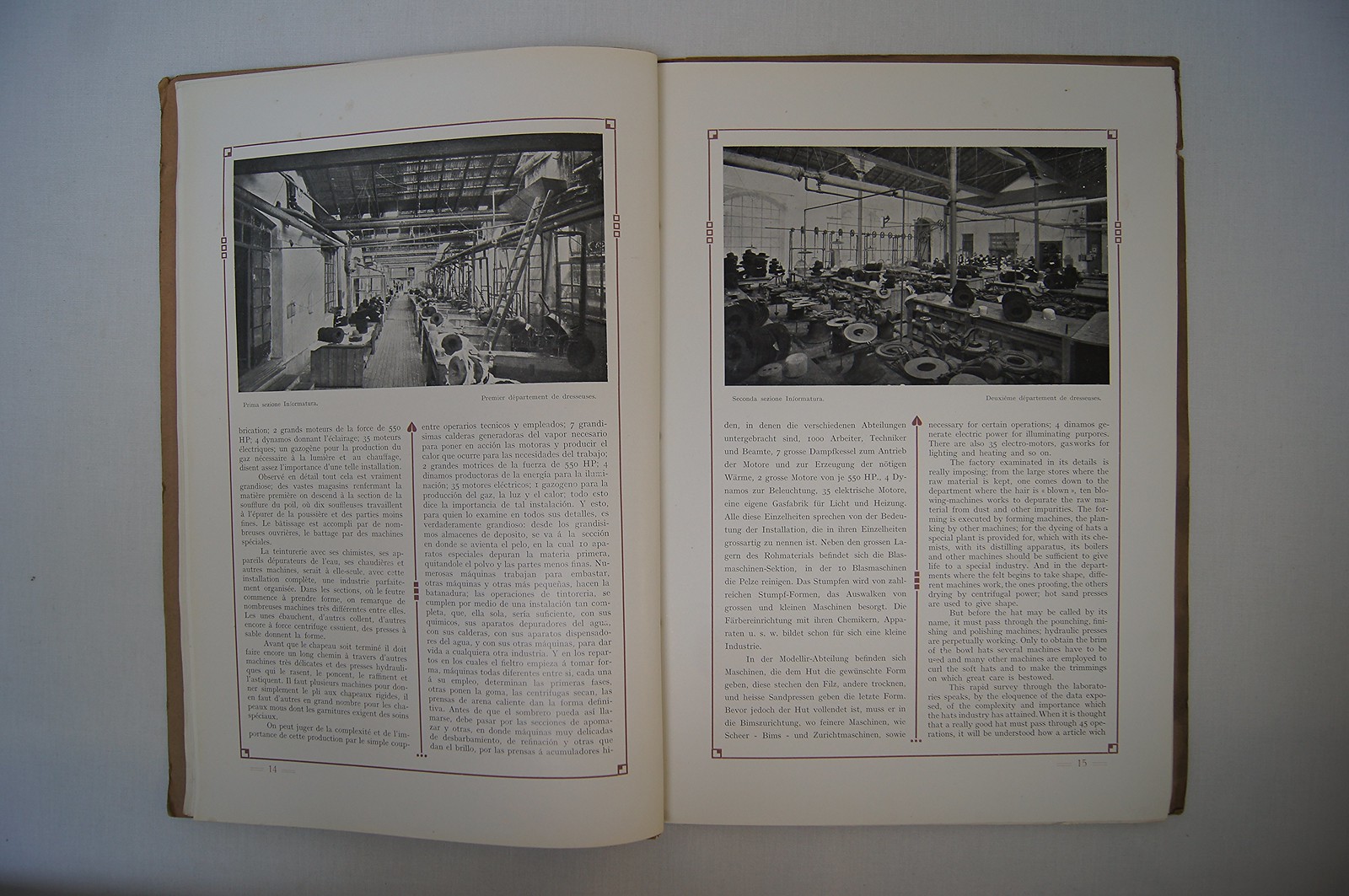

(left) First Section Hat Body Stretching and Blocking (right) Second Section Hat Body Stretching and Blocking

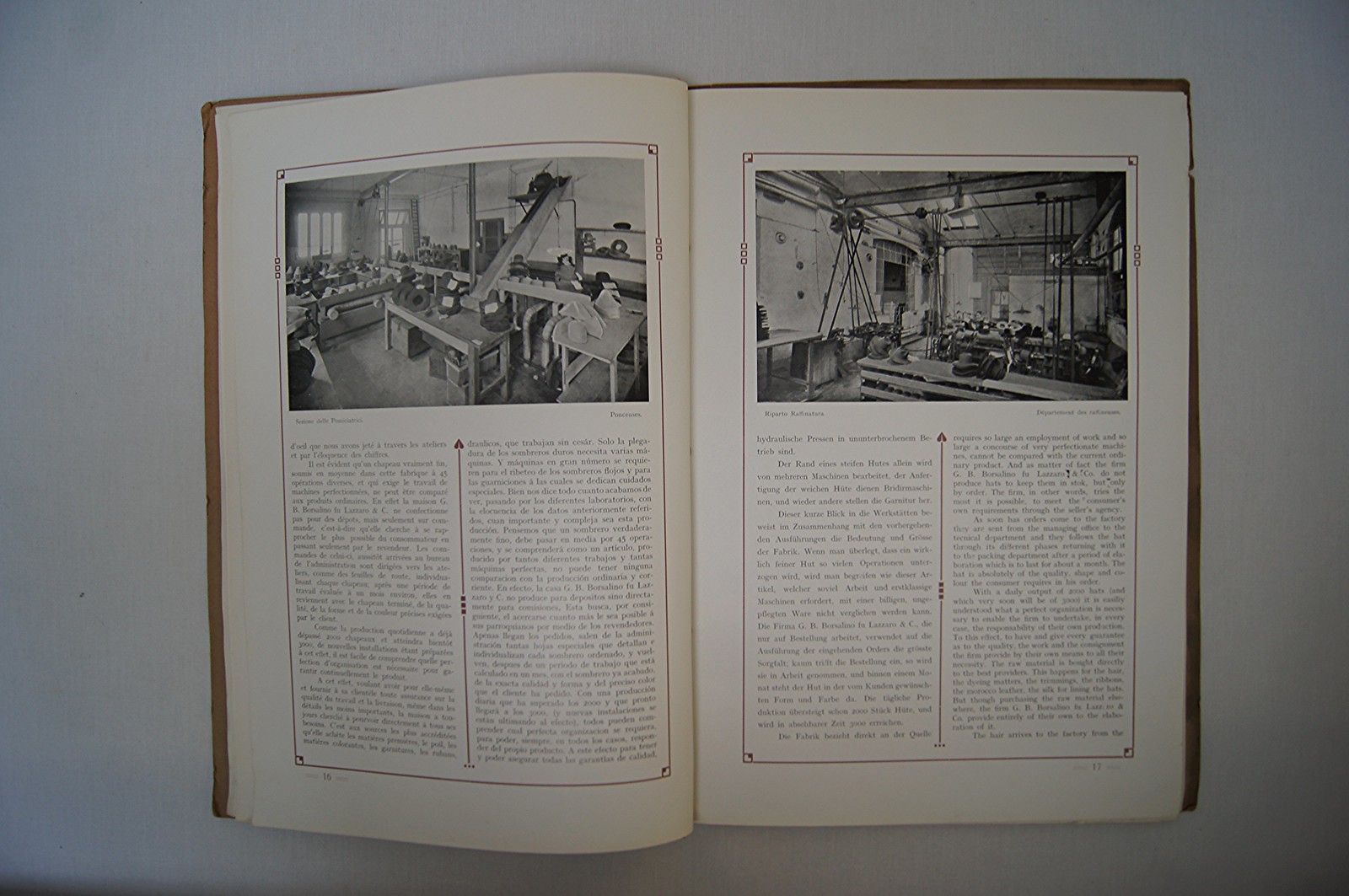

necessary for certain operations; 4 dynamos generate electric power for illuminating purposes. There are also 35 electric motors, gasworks for lighting and heating and so on. The factory examined in its details is really imposing: from the large stores where the raw material is kept, one comes down to the department where the hair is blown by ten blowing-machines works to depurate the raw material from dust and other impurities. The forming is executed by forming machines, the planking by other machines: for the dyeing of hats a special plant is provided for, which with its chemists, with its distilling apparatus, its boilers and other machines should be sufficient to give life to a special industry. And in the departments where the felt begins to take shape, different machines work, the ones proofing, the others drying by centrifugal power: hot sand presses are used to give shape. But before the hat may be called by its name, it must pass through the pouncing, finishing and polishing machines: hydraulic presses are perpetually working. Only to obtain the brim of the bowl hats several machines have to be used and many other machines are employed to curl the soft hats and to make the trimmings on which great care is bestowed.

This rapid survey through the, laboratories speaks, by the eloquence of the data exposed, of the complexity and importance which the hats industry has attained. When it is thought that a really hat must pass through 45 operations, it will he understood how a article which

(left) Trim Department (1896?) (right) Dynamo

(left) Boilers (right) Boilers

(left) Receivables (right top) Hair Sorting (right bottom) Cone Forming

(left) Mechanical Fulling (right) Manual Fulling

THE name of Alexandria. the ancient and industrious piedmentese town. is today deservedly. all over the world synonymous for ,,, fine felt hat ,, just as Malines and Valenciennes are for lace. Faience for crockery. Sevres and Delft for porcelain-ware. the Havana for cigars. Panama and Manilla for straw hats, Tolede for blades, Smyrne for carpets. Astrakhan for skins and so on.

The felt hats industry has certainly become. with the spreading of comfort and elegance, with the continuous varying of the mode, one of the hardest and delicatest, wherever it wants not only to follow the changing of taste, but also to dominate and direct it and wherever the industry is not compelled to limit its field of action to the preferences of only a people (which preferences are often due to special conditions of use and climate), but to enlarge them as to comprehend and satisfy all modern exigences.

An old tradition in the felt hats industry has brought up in Alexandria the most skilled workmanship in each one of the various operations (from the very humblest to the most difficult one) through which the hair passes to become felt, and the felt to be molded in a hat: there exists among the Alexandrine workman-ship, an experience almost hereditary. transmit-ted from father to son, which has educated the eye and the hand at such a degree as to give the industry a coefficient of a inestimable value.

To such a workmanship, so much capable h their own skillfulness and by tradition, it must be added the truly powerful organic-

(left) Felt Warehouse (right) Dyeing Department

tion created for the best exploitation of these qualities and conditions by the firm G. B. Borsalino fu Lazzaro & Co. It is enough to say that a particular group of workmen attends to every one of the 45 operations that hats must pass through; as they perform only a operation and always the same, these workmen are beco-ming specialized in a truly perfect way. Each group of workmen have their own chief. who oversees uninterruptedly their work and this accounts for a product completely free from faults, even the slightest ones. To all that it must also be added the fact, that by means of the processes used in the G. B. Borsalino fu Lazzaro & Co. factory it is possible to obtain the lastingness and the immutability of form and colour. two qualities greatly appreciated by customers and forming one of the specialties of the firm. The weather and the long wearing do not have a influence whatever on G. B. Borsalino fu Lazzaro & Co. hats which claims to a lastingness superior to every other product of this kind.

To give an idea of the industrial organization of the factory some data are sufficient: the capital amounts-tor the time being-to 3.500.000 francs: the grounds on which the work is carried on, cover an area of 39.000 square feet and the various building have two, three or four stories. according the necessity, to the end of keeping the various departments in a logical relation between them: tow clerks and workmen are employed in the factory: 7 enormous boilers provides steam for two engines of 550 HP

(left) First Section Hat Body Stretching and Blocking (right) Second Section Hat Body Stretching and Blocking

necessary for certain operations; 4 dynamos generate electric power for illuminating purposes. There are also 35 electric motors, gasworks for lighting and heating and so on. The factory examined in its details is really imposing: from the large stores where the raw material is kept, one comes down to the department where the hair is blown by ten blowing-machines works to depurate the raw material from dust and other impurities. The forming is executed by forming machines, the planking by other machines: for the dyeing of hats a special plant is provided for, which with its chemists, with its distilling apparatus, its boilers and other machines should be sufficient to give life to a special industry. And in the departments where the felt begins to take shape, different machines work, the ones proofing, the others drying by centrifugal power: hot sand presses are used to give shape. But before the hat may be called by its name, it must pass through the pouncing, finishing and polishing machines: hydraulic presses are perpetually working. Only to obtain the brim of the bowl hats several machines have to be used and many other machines are employed to curl the soft hats and to make the trimmings on which great care is bestowed.

This rapid survey through the, laboratories speaks, by the eloquence of the data exposed, of the complexity and importance which the hats industry has attained. When it is thought that a really hat must pass through 45 operations, it will he understood how a article which

Edit: http://offer.ebay.com/ws/eBayISAPI.dll?ViewBids&item=291690723398

Edit: http://offer.ebay.com/ws/eBayISAPI.dll?ViewBids&item=291690723398