Woodtroll

One Too Many

- Messages

- 1,273

- Location

- Mtns. of SW Virginia

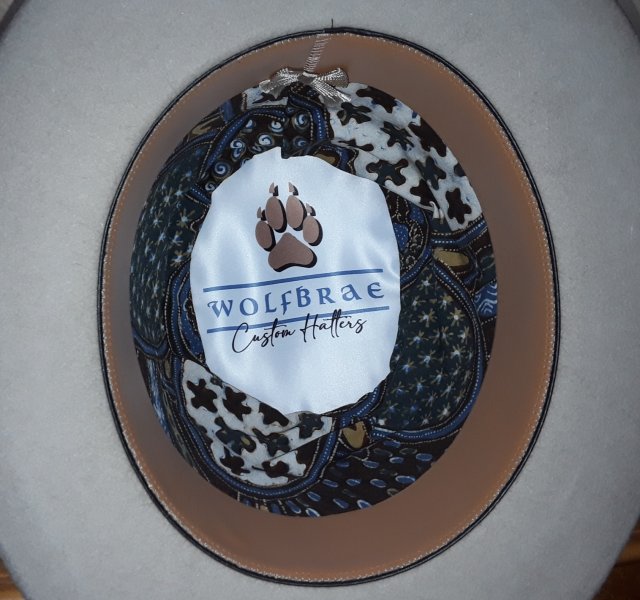

Another Wolfbrae wonder! Great hat and a great color combo.

Thank you, Randy, much appreciated!

Another Wolfbrae wonder! Great hat and a great color combo.

I received my new Wolfbrae from Robert this afternoon, and I love it! It is a Wanderer clone of sorts. He sent it open crown so I could bash it myself and I put a teardrop in it as soon as I got home for work today.

As bashed it is a 4 1/2" crown and it has a 2 1/2" bound snap brim. Robert found the perfect color 20 mm ribbon.

View attachment 545690 View attachment 545691 View attachment 545692 View attachment 545693 View attachment 545694 View attachment 545695

Looks great on you Simeon. Beautiful job by RobertI received my new Wolfbrae from Robert this afternoon, and I love it! It is a Wanderer clone of sorts. He sent it open crown so I could bash it myself and I put a teardrop in it as soon as I got home for work today.

As bashed it is a 4 1/2" crown and it has a 2 1/2" bound snap brim. Robert found the perfect color 20 mm ribbon.

View attachment 545690 View attachment 545691 View attachment 545692 View attachment 545693 View attachment 545694 View attachment 545695

Another Wolfbrae beauty.

Looks great on you Simeon. Beautiful job by Robert

Very nice!I received my new Wolfbrae from Robert this afternoon, and I love it! It is a Wanderer clone of sorts. He sent it open crown so I could bash it myself and I put a teardrop in it as soon as I got home for work today.

As bashed it is a 4 1/2" crown and it has a 2 1/2" bound snap brim. Robert found the perfect color 20 mm ribbon.

View attachment 545690 View attachment 545691 View attachment 545692 View attachment 545693 View attachment 545694 View attachment 545695

Congratulations RobertAnother grand day; I just approved the final draft of my first article on hatting for the online magazine, HaTalk. If all goes well I will have a monthly column devoted to crafting fedoras. The magazine has been focused on the millinery trade and I have been added in an attempt to broaden the appeal into Men's Hatting concerns (women too!). The first article is on felts. Apparently I am too wordy and the editor has split the article into two pieces so part two will be next month.

No pictures yet but today I placed an order at the embroidery shop. I am upgrading my liner tips to embroidery from printed.

I placed a small order for a trial run and if it works well I will be offering embroidery on all my hat liners.

I could not match the colours in my printed logo very closely so I am hoping the final embroidery looks good. That is why I only did a small run as a trial.Nice upgrade. Count me in.

Back last night from our two week jaunt in Dixie. One of the great highlights was our visit to Winchester Felts in Winchester Tennessee. I phoned two days prior asking if I could drop in and just poke my head in the door to just view the factory floor.

Trish said she would check with Jeff to see if he was available.

Yes, was the answer.

Not only did I get to pop into the factory but Jeff gave us a grand tour through each of the felting steps. It was a dream come true for me to actually see the fibre turned into a felt and turned into the rough makings of a hat.

The aspect that struck me is how UNautomated the process is. Yes, there is machinery (vintage in most cases) but no automation, no real production line but each felt is handled by a real human at each step in the process. Each felt is put through its paces by the touch of a human hand and each felt is turned into hat makins' by real human beings.

What I learned: Winchester does not process the animal pelts. They buy the fibre in large bales processed and ready to felt.

They have stock on rabbit, beaver and nutria. It was great to handle the raw fibre and feel the difference between the 3 animal's fibre.

Availability of the processed fibre is NOT the issue. Winchester runs one shift, 6 days a week. They have the demand to run 2 shifts a day but the core issue is a shortage of labour.

Winchester is located about an hour south/east of Nashville. As Jeff stated: "No one seems to want to work these days."

Even with the one shift they are short workers. They have 3 machines that do the main job of felting and lately they have been able to man just 2 of them so the 3rd machine sits idle. Combine this with the increased demand for felts and you have delivery delays.

Jeff stated that he has customers that in previous years were ordering 200-300 felts are now ordering 1000. Couple that with the labour shortage and you have lengthy deliveries.

One other thing Jeff mentioned is the sharp increase in the price of nutria in the US. It seems again created by a labour shortage. Nutria is hunted for a government funded bounty. There is a shortage of hunters these days, a shortage of pelts and the price has risen from a dollar or two per pelt to upwards of $7+. Jeff says he can see Nutria disappearing for Winchester as a felt in a couple of years. Nowadays they use it primarily as a filler/additive to the rabbit felts to help give substance/durability. But it is not that big a deal and if the price/supply issues linger they will phase it out.

It was a glorious day and it may sound silly but it was the fulfillment of a dream to see the factory.

Gigi is opening up a new store soon right in Winchester. I bought a straw hat in the Nashville store as I left mine at home by mistake. The clerk that helped me responded when I asked about the covid era dispute with Stetson and he replied that Stetson actually came 'crawling' back to them and asked for GiGi to offer Stetson hats. So all is well with Hatwrx.Great that you got to visit the plant!!!! Jeff is a great guy and I know you recieved a very informative tour.

This photo is from when Greg Fisk retired and Jeff was handed the reins[03/2019].

left to right front

Mike Moore [Buckaroo Hatters] Steve W Stratton [Stratton Hats] Richard Bean [Winchester] Jeff Tetter [Winchester] GiGi Gaskins [HATWRKS]

left to right back

Greg Fisk [Winchester] Steve Stratton [Stratton Hats] Gunner Foxx [Gunner Foxx Hats]

RBH [me]

John Lofgren Monkey Boots Shinki Horsebuttt - $1,136 The classic monkey boot silhouette in an incredibly rich Shinki russet horse leather.

John Lofgren Monkey Boots Shinki Horsebuttt - $1,136 The classic monkey boot silhouette in an incredibly rich Shinki russet horse leather.  Grant Stone Diesel Boot Dark Olive Chromexcel - $395 Goodyear welted, Horween Chromexcel, classic good looks.

Grant Stone Diesel Boot Dark Olive Chromexcel - $395 Goodyear welted, Horween Chromexcel, classic good looks.  Schott 568 Vandals Jacket - $1,250 The classic Perfecto motorcycle jacket, in a very special limited-edition Schott double rider style.

Schott 568 Vandals Jacket - $1,250 The classic Perfecto motorcycle jacket, in a very special limited-edition Schott double rider style. I just had one of my most satisfying experiences as a hatter this morning. A fellow my age give or take contacted me a while back and opened with..."you probably won't be able to help me but thought I would ask.....".

As a child he admired his father's fedoras but could never try them on as his head was much larger than his dad's. As an adult he wore bucket hats, baseball hats but could never find a fedora he liked that fit. It seems his size 63cm long oval head proved impossible to fit with an off the rack hat.

But he came across the article in the local paper and thought he would give it a shot.

Today he came back for a fitting and to choose the trim. I nailed the fit...more on that later.

He wanted a casual, what I call Country Gentlemen or Crossover hat, and I showed him a number of my hats with both leather bands and traditional ribbon/bow. I suggested I make him a custom leather band but he kept coming back to the ribbon. He said it reminded him of his father's hat and although it was more formal than he visioned he really leaned in that direction but hesitated that it would look too formal and not 'him'..

I advised that I had the solution. I would make him the hat with the ribbon/bow and he wear it for 6 months. If, at that time, he decided it was just not for him I would make him a leather band to replace the ribbon.

The smile he had on his face when he tried on the unfinished hat and looked in the mirror was priceless. He loved the hat, loved the colour, loved the proportions, and most importantly HE thought he looked good in it and now, finally, in his 7th decade he finally had his good hat AND one that fit his large head perfectly.

Days like this............