jhe888

One of the Regulars

- Messages

- 265

- Location

- Texas, United States

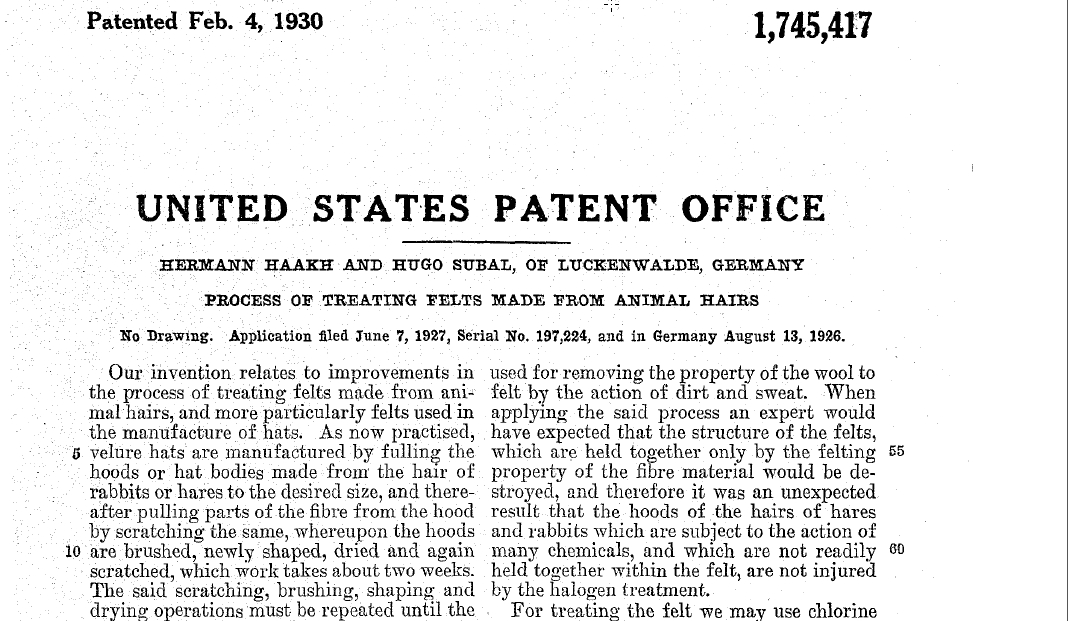

I have Googled for information about velour felt, with very little success.

Who can tell me about it, or provide a link to something? I believe it is fur felt, but know little more than that. Is it a different fur, a different way of making the felt, a different finish to the same basic felt, or a combination of those?

Is it made any more?

Once it is a hat, does it need different treatment or behave differently than "regular" felt?

And, of course, who can post some photos?

I hope this will generate more than just a quick answer, so I started a thread instead of adding this to "Ask a question."

Thanks.

Who can tell me about it, or provide a link to something? I believe it is fur felt, but know little more than that. Is it a different fur, a different way of making the felt, a different finish to the same basic felt, or a combination of those?

Is it made any more?

Once it is a hat, does it need different treatment or behave differently than "regular" felt?

And, of course, who can post some photos?

I hope this will generate more than just a quick answer, so I started a thread instead of adding this to "Ask a question."

Thanks.