- Messages

- 12,384

- Location

- Albany Oregon

The crown iron came from a shut down hatter I think. He had a machinist spiff it up and install a power system that is modern and controllable. I only saw it work without a hat in it, but it is really cool. In it's day, it was belt driven from above. I'm sure you could call him and he would be more than happy to talk about it. He is a great guy and loves to talk hats!View attachment 76267

This is a Doran brothers crown iron. Did Mike mention where he found this? I have used it at JW Hats in Utah but outside of that I haven't seen them anywhere.

View attachment 76269

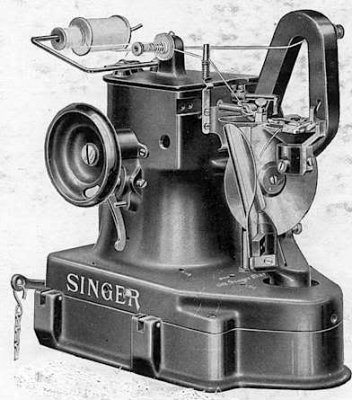

Super curious what this thing is. Any ideas?

http://www.thefedoralounge.com/attachments/76269/

This press works with steam to press and shape hat brims and crowns (I think). All this stuff is magic to me. All I know is that he produces the most wonderful custom hats. His efficiency is going to be greatly enhanced by these additions. When we were talking the issue of "hand made hats" came up, he shared that his hats are still "hand made", just like the hat companies of the golden age with these vintage machines.