Silver-Wolf

One of the Regulars

- Messages

- 190

- Location

- South Australia

I use what my grandfather used for his hat (well all his leather items, saddle, boots etc even all his wooden gear and furniture I think he used it on.) and that's just a simple bee's wax with orange oil. Only ever so lightly, more I just get my finger greasy and then rub the leather band when the weather is warm. I let it sit for an hour and then rub and wipe all the leather with a clean cloth. He always said the trick is to not get too much on areas of stitching etc because if it builds up stitching could rot.

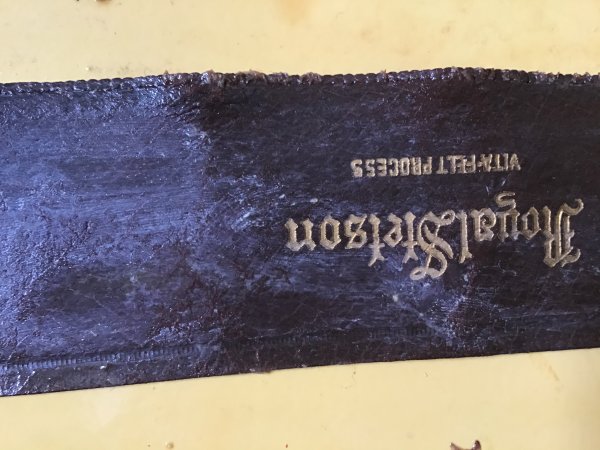

edit: Added a couple of pics of my oldest/most abused and worn hat after DIY refurbishment and adjustment. Man it came up clean, just had a fresh rub of beeswax.

Never noticed till now looking at this photo, being my most worn hat it's conformed to my noggin shape best. Off-topic slightly but I must be long oval as you can see looking at the sides and front/back on the inner hat band.

You can see some of the crown at brim level at the sides while stitching stays true front 'n back but you can see how it has come in at the side to meet my head and block.