Matt Deckard

Man of Action

- Messages

- 10,046

I’ll post more on Decatising and how it’s done with hats as time goes by. But here’s a short vid with a short explanation.

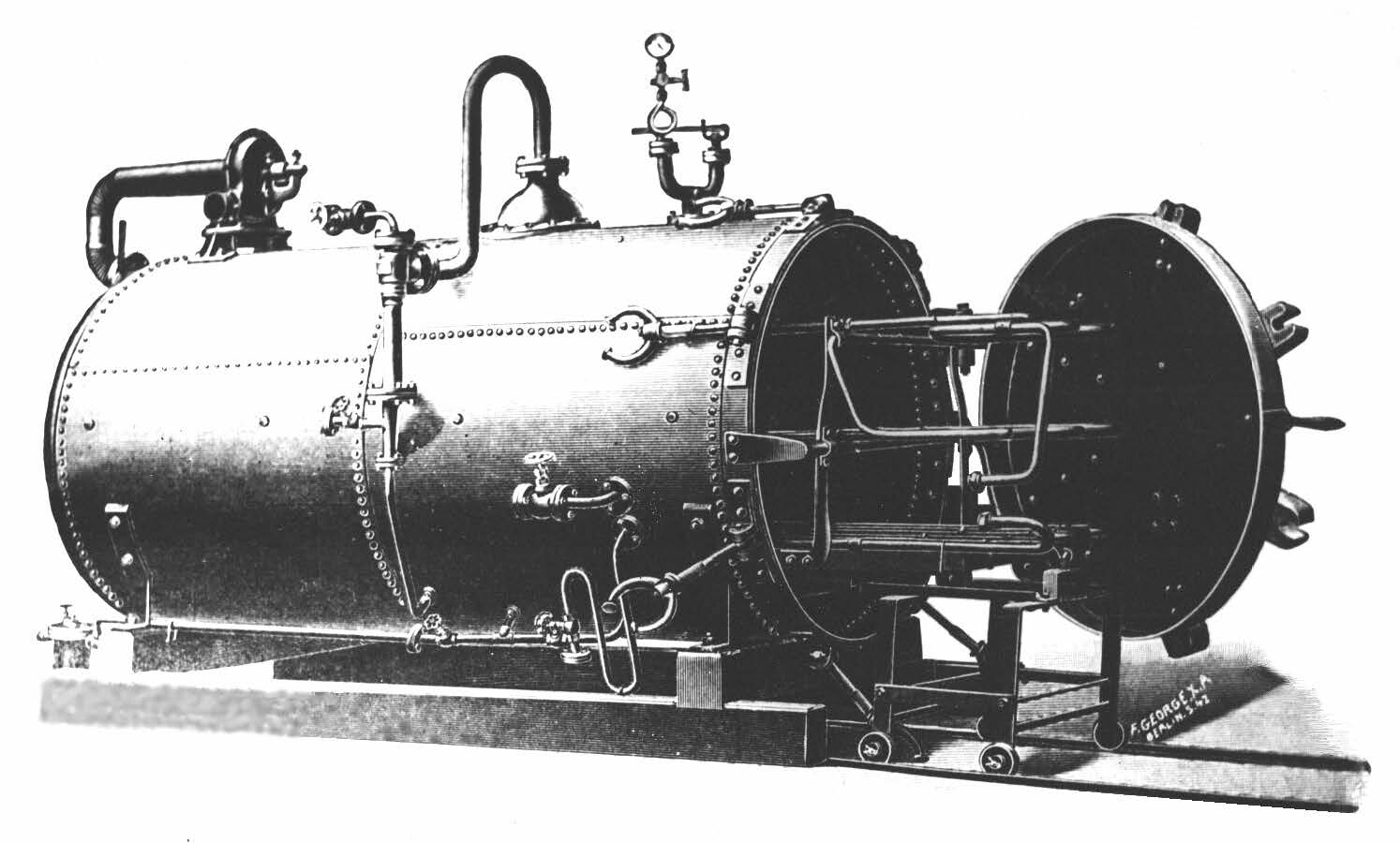

Felt decatising is very different from working with a woven cotton or wool fabrics and a few different machines are required.

DECATISING

Stiffened hats that haven’t been decatised tend to shrink less when soaked, less than soft felts as the shellack applied holds the hairs in place and prevents them from refelting tighter. But the biggest issue is the oils in the felt that need to be broken down through cold and heat. But this can also make for drier feeling felt like can be found in many of the vintage hats that can hold their shape, but may be able to take being repeatedly pinched without cracking because the oils have been rendered inert over time.

The opening photo is a vintage Knox, in the video I’m wearing an ultra light 2016 Stetson Excellent Quality Whippet I whipped up at the factory as Creative Director.

Felt decatising is very different from working with a woven cotton or wool fabrics and a few different machines are required.

DECATISING

Stiffened hats that haven’t been decatised tend to shrink less when soaked, less than soft felts as the shellack applied holds the hairs in place and prevents them from refelting tighter. But the biggest issue is the oils in the felt that need to be broken down through cold and heat. But this can also make for drier feeling felt like can be found in many of the vintage hats that can hold their shape, but may be able to take being repeatedly pinched without cracking because the oils have been rendered inert over time.

The opening photo is a vintage Knox, in the video I’m wearing an ultra light 2016 Stetson Excellent Quality Whippet I whipped up at the factory as Creative Director.

Last edited: