thunderw21

I'll Lock Up

- Messages

- 4,044

- Location

- Iowa

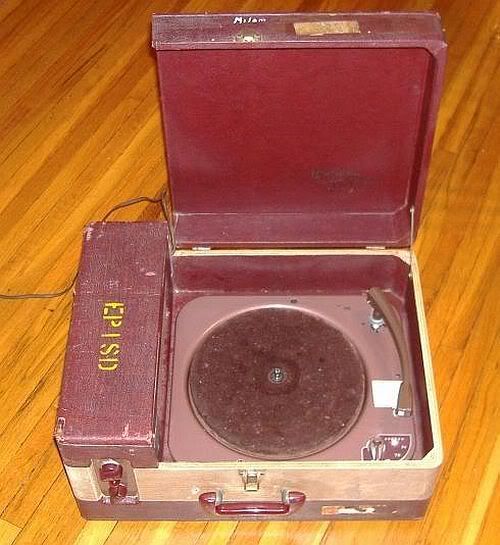

I have a 1950s portable phonograph (about the size of a small suitcase) that has variable speeds: 33, 45 and 78. About a year ago the 33 speed slowed way down while the 45 and 78 remained normal. Since 33 rpm is what I mainly use, I can't listen to anything without it being obscenely low and slow.

Does anyone know of a reason for this slowing down and what could be done to fix it?

Does anyone know of a reason for this slowing down and what could be done to fix it?