spectre6000

One of the Regulars

- Messages

- 192

Right off the bat, I want to be very clear here. I have never made a pattern. I have never made a garment. I am learning this as I go. I am not an expert. Disclaimer accomplished.

Meanwhile, over on page 401 of the Fivestar thread, I stole some of my daughter's art supplies and started messing around. I had a design that looks good in 2D on paper, and given the fact that Fivestar will make whatever without any guard rails against things that just don't work, I wanted to make sure that it would actually work in real life like it did in my head. Spoiler alert. Noop. Sorta. A little. Enough to make me want to keep messing with it. But, no.

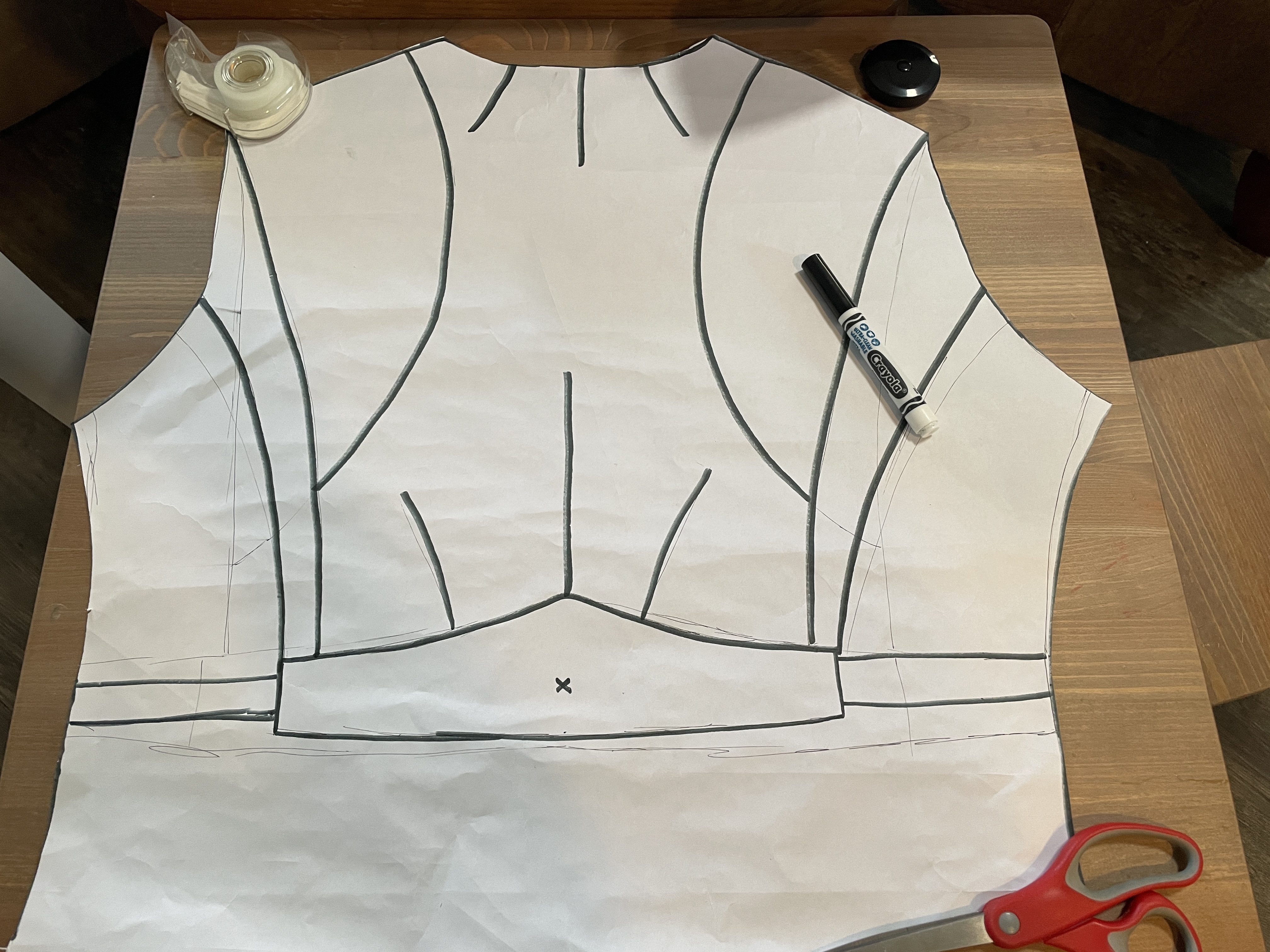

The design drawn large, but ultimately a sketch of a jacket laid flat on a table top... laid flat on a table top.

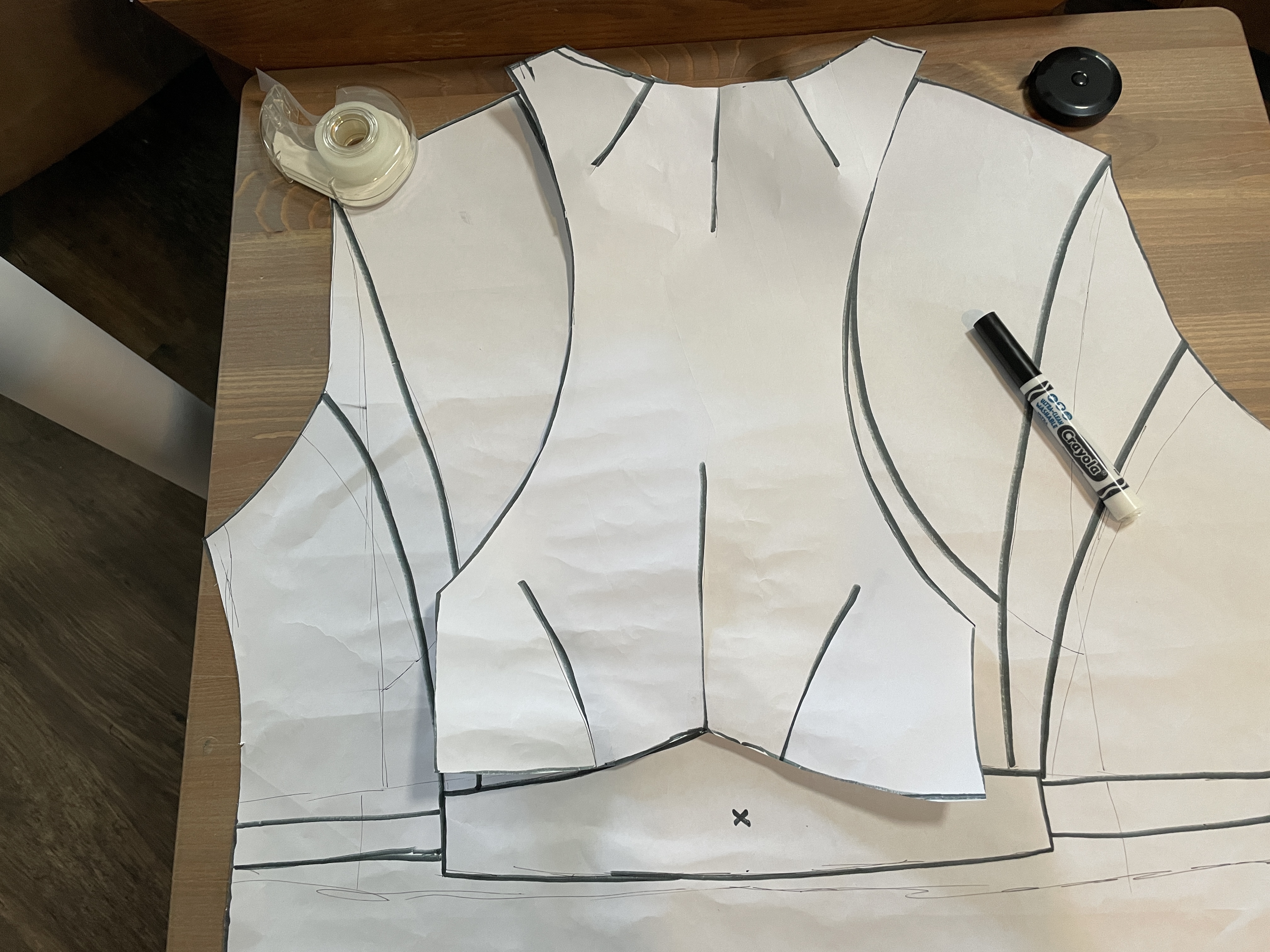

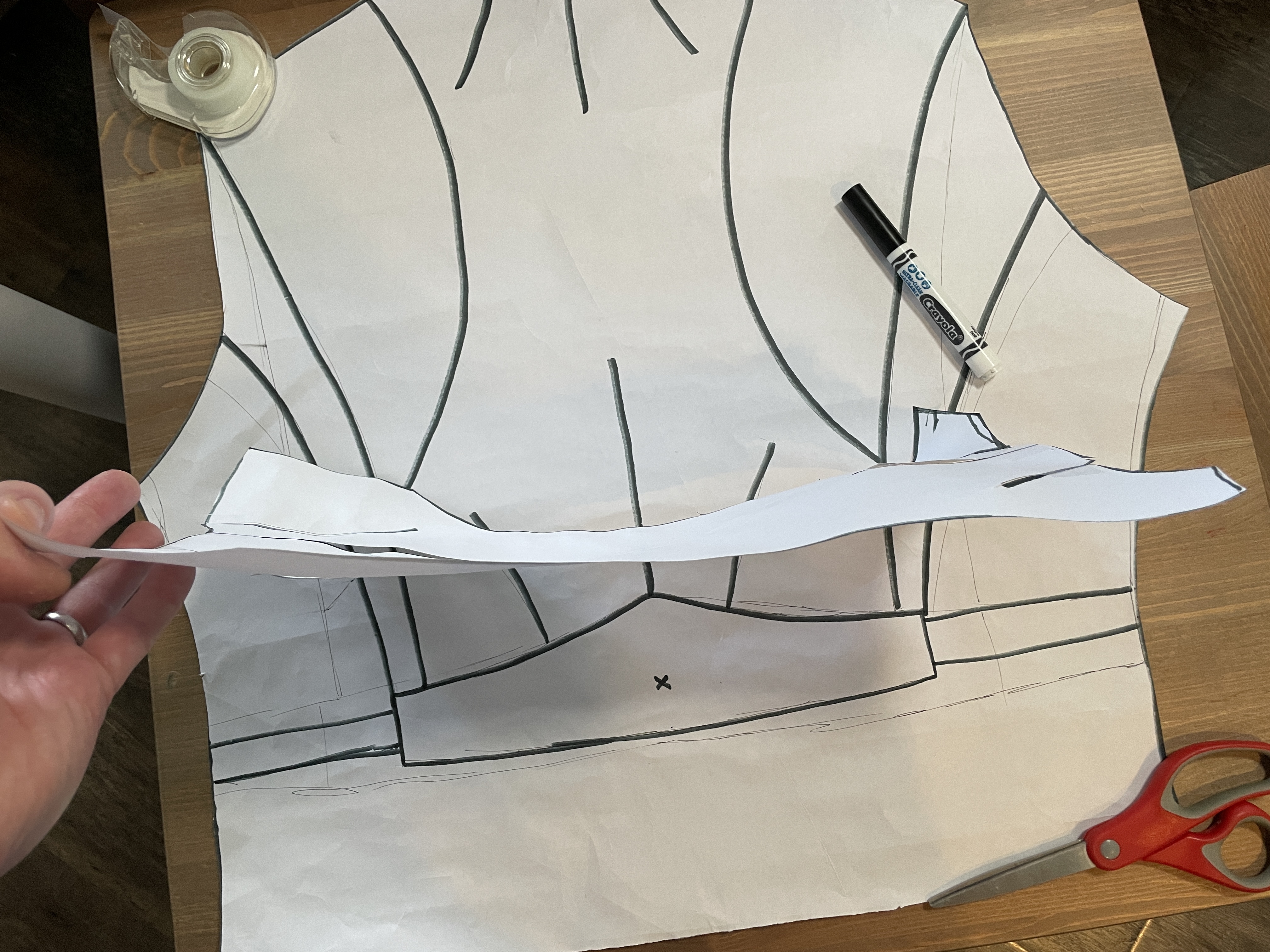

Then I duplicated it, cut it out, and cut through where the darts were in my drawing.

Then I messed around with the angle that the darts were overlapped onto themselves, and taped them. The result was the below.

The aim was to match the curvature of my back.

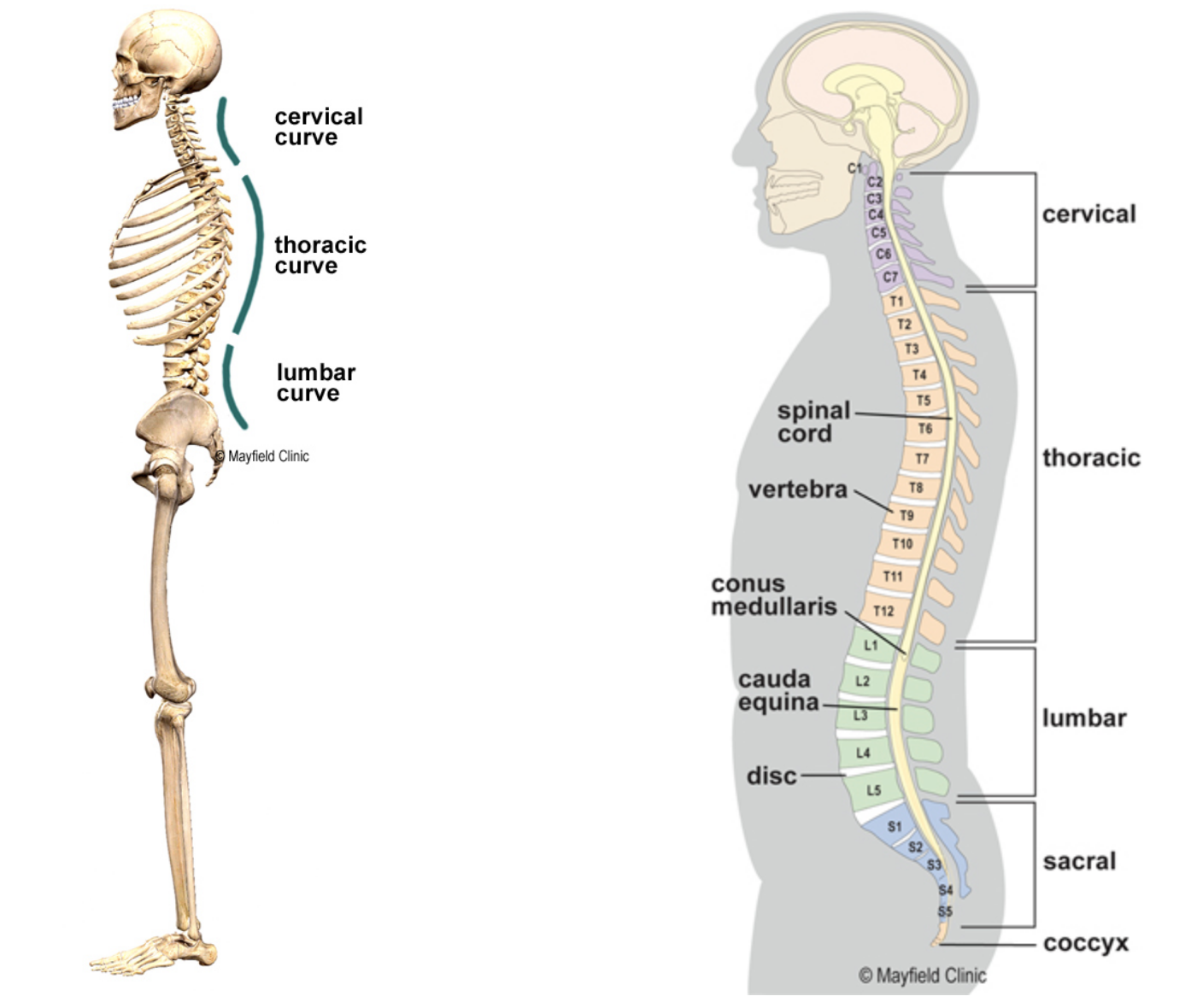

The problem is that the panel stops at my waist, which is where the thoracic curve turns into the lumbar curve... It's got an S-curve, but that's not what's supposed to be happening in that panel. So...

Fortunately, at this point, my wife stepped in. She's quite the sewing hobbyist with a background in theatre (not your typical tech company IT Director). She flushed all of that for me, and pointed me in the right direction. She started out by pulling out a pattern for a generic bodice. Obviously, it's a women's pattern, but backs is pretty much backs. She took my measurements, and printed me up a bodice pattern that was more or less my measurements, and I used it to make another paper template. I drew my darts onto this, and we played around with it.

Unfortunately, at this point in the process, I didn't really know what I was doing, where I was going, or how I was going to get there. This thread was not on my radar, and so documentation is unfortunately lacking. Fortunately, wife had a clue, and did her best to preserve my design while making the curve actually work. We organically found ourselves with a fairly classic set of darts as described here. Again, this is oriented toward female garments, but backs is backs.

Ultimately, we found ourselves here:

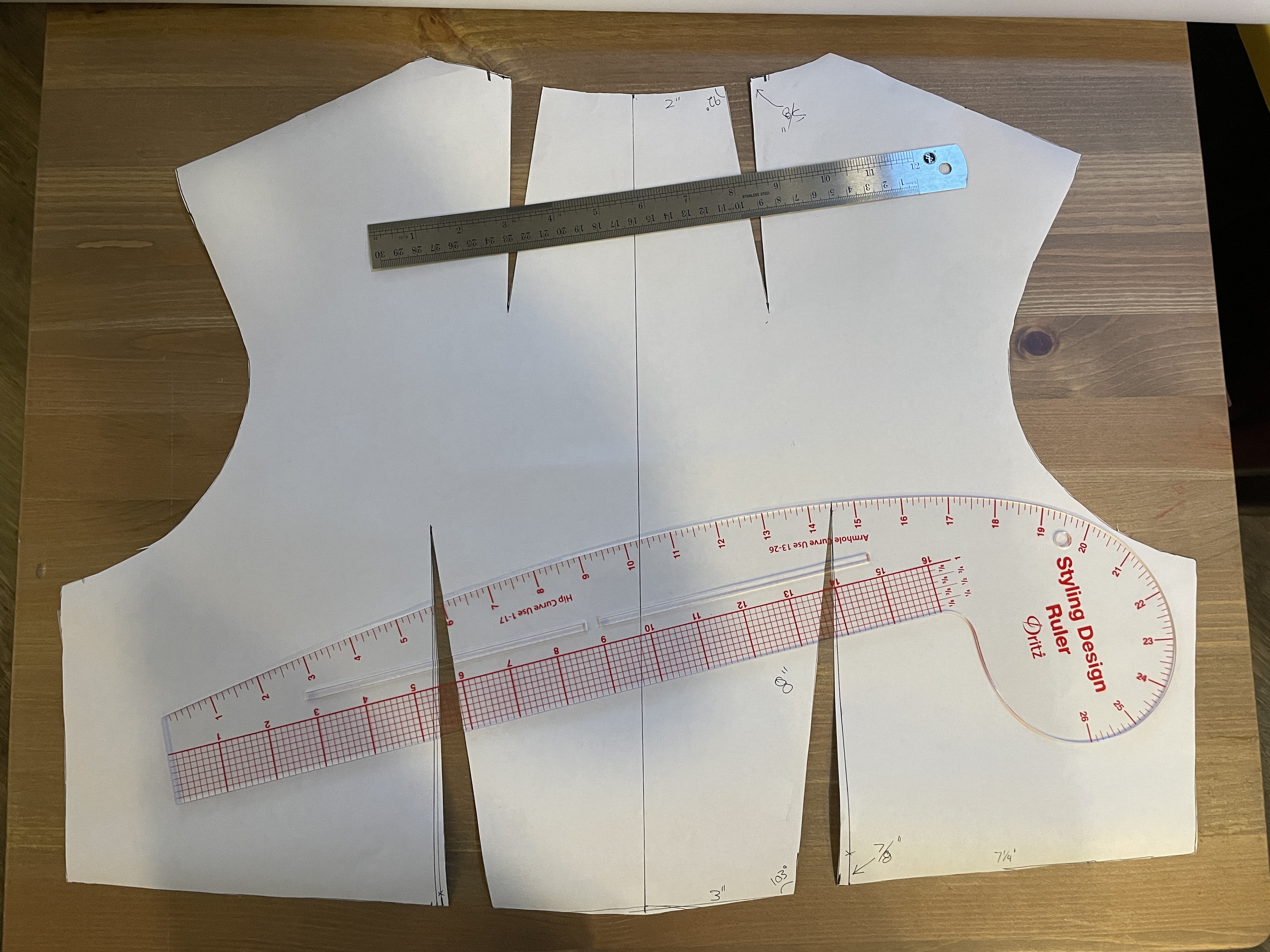

The pattern totally flat showing the location, angle, length, and width of the darts (zoom in for actual numbers):

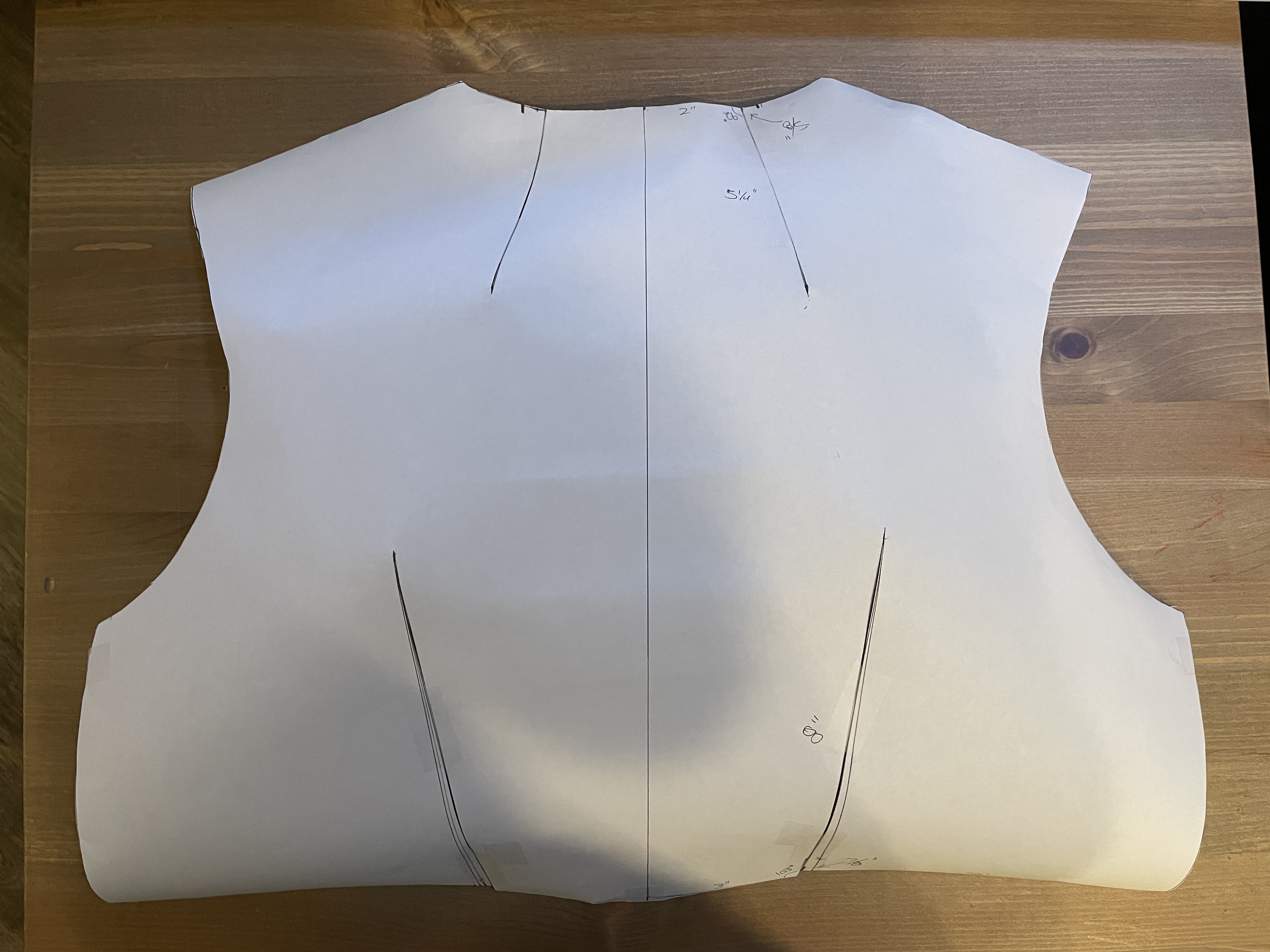

Darts connected, but with the pattern laid flat. This makes it extra domey, because it sort of flattens out when it wraps around your torso:

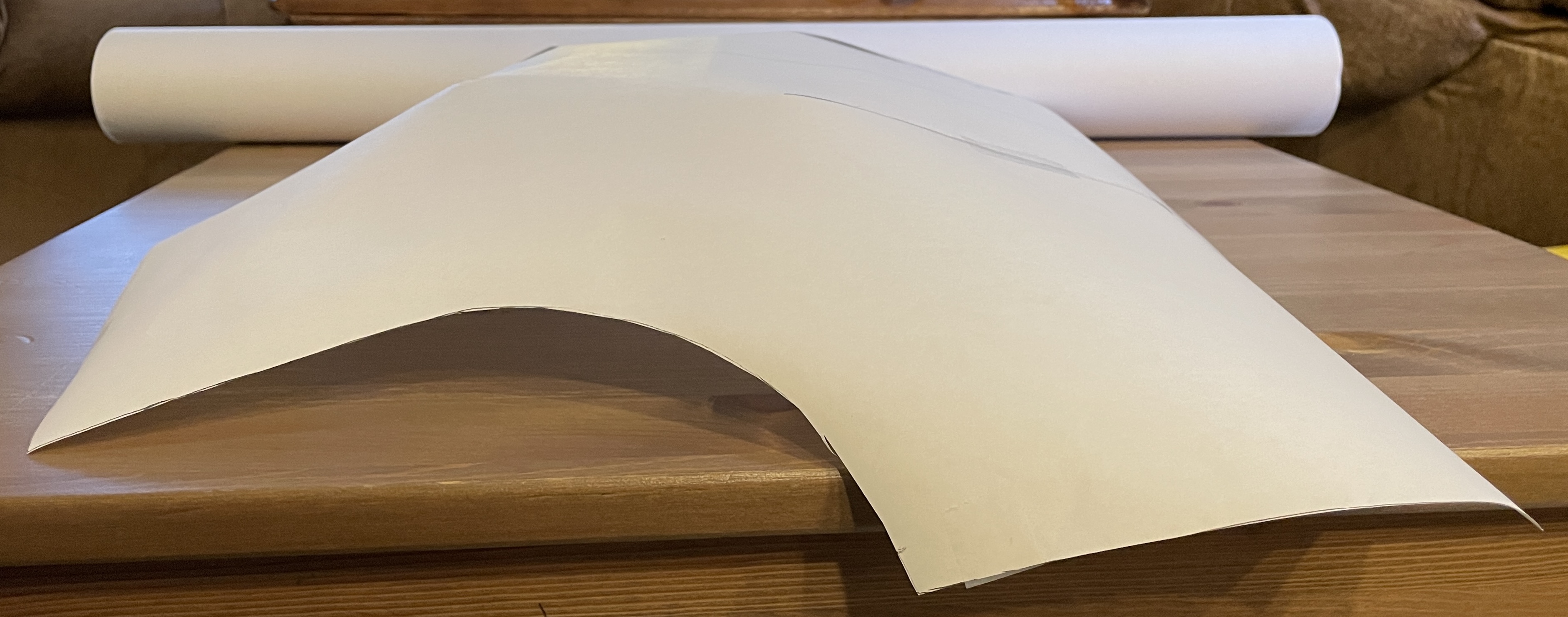

From the side, still flat on the table:

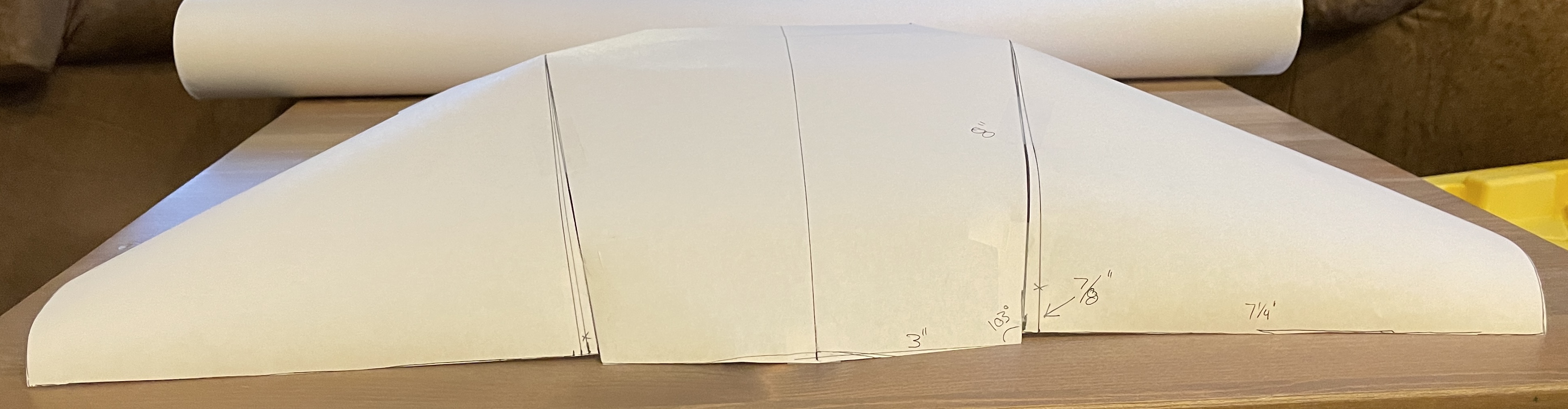

From below, still flat on the table:

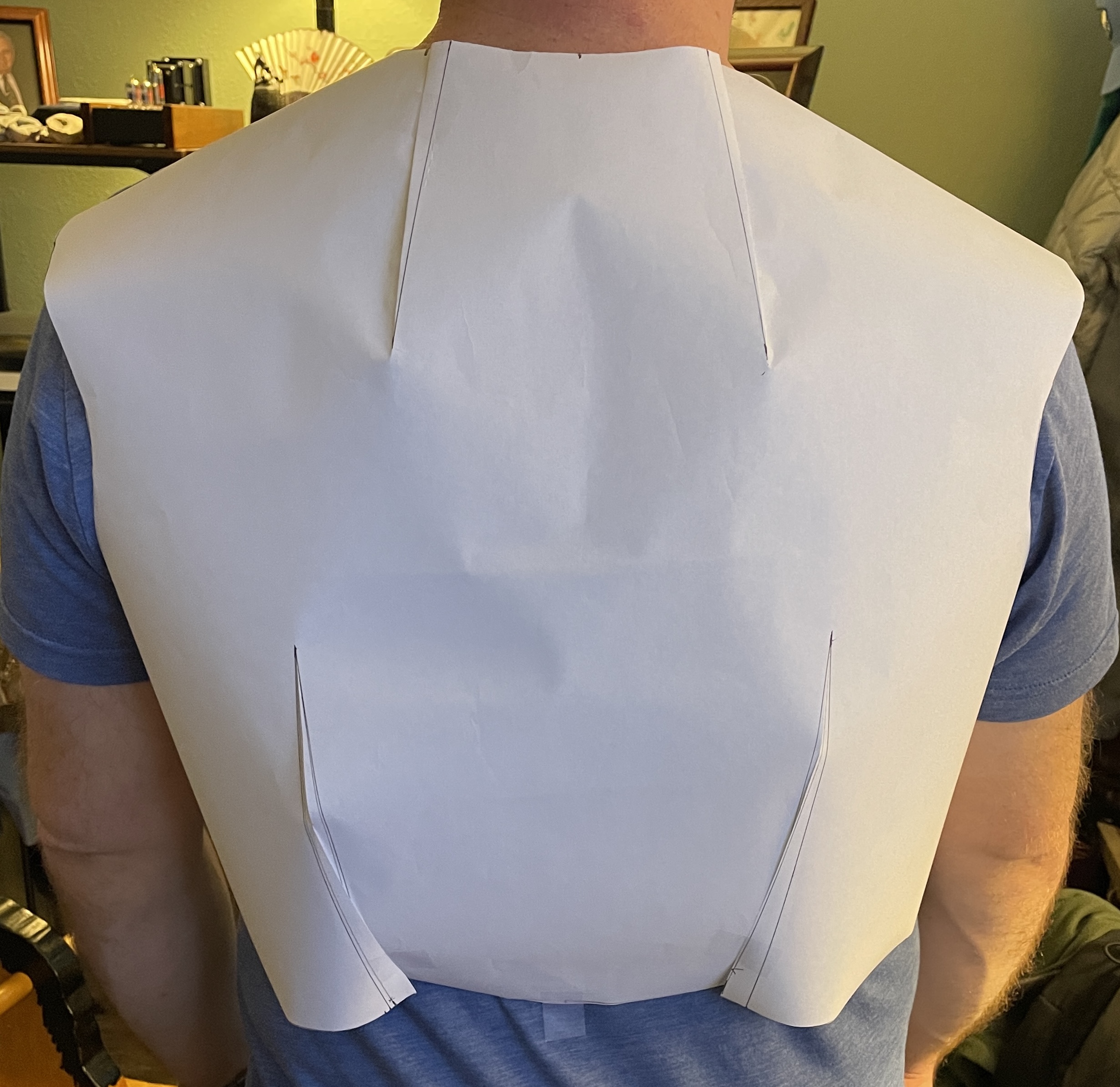

Here's another documentation lapse... We used scotch tape (the kind that releases easily) to tape the pattern to my shirt, and I moved all around. Arms in a full circle, touched my toes, rocked at my waist, etc. In the process of doing so, my shirt shifted around, so where the pattern initially sat exactly on the seams on my shoulders, for instance, it got a little twisted and my shirt bunched up. It makes the pattern look a little disheveled, but the fact that it's still attached using only "magic release" Scotch tape really shows how well this fits.

Straight on:

From the side:

The pattern at this point matches the curve of my back pretty much exactly. If it were the back panel of a jacket, it would be skin tight. This might actually not be the worst thing in the world, but I want some ease for layering and weight fluctuation.

What I learned from this exercise:

The goal was to figure out how darts work so that my design for Fivestar turns out like I want it to. Here's what I figured out:

- The darts need to point to the high spot. In this case, shoulder blades.

- If they're too wide/the angle is too large, the result will be a point instead of a dome.

- The angle of the dart affects the resulting curve, but it's sort of a complex relationship that's hard to explain, assuming I even understand it. The arch appears to form mostly perpendicular to the dart, so you want the darts oriented accordingly from the major seam adjacent. If you angle the dart like I did at the start, it just kinda does weird stuff. There's probably a way to mess with the angle to fine tune things a little more, but I'm not there yet.

- Longer darts make for tighter curves. Wider darts also make for tighter curves.

Again, just to stress, I do NOT know what I'm doing here. Playing it by ear. I believe the next step is to make the back panel larger for ease. Doing this at the seams/edges is pretty straight forward: bigger is bigger. If I add an inch to each side, that's the equivalent of 4" ease (I think) with 2" in the back panel and the same in the front panel. With the darts, that means I need to make them shorter, but I have to make them narrower proportionally. The pattern makers' ruler is clear with those 1/8" lines. I can incrementally shrink the darts proportionally using those lines. Setting the ruler down so that the 1/8" line is on top of the dart lines, and then trace the edge. Then just iterate.

Unfortunately, that means I need to cash in some social capital with wife. In a perfect world, I'd have a dress form. In this one, I just have me. It's hard to do my back since it's... you know... back there. Can't really reach or see what I'm doing. I'll hopefully get to this this weekend, and I'll try to document better going forward as I figure this out.

Also on the "next steps" list is the front equivalent of this back plate. That will hopefully be simpler.

Meanwhile, over on page 401 of the Fivestar thread, I stole some of my daughter's art supplies and started messing around. I had a design that looks good in 2D on paper, and given the fact that Fivestar will make whatever without any guard rails against things that just don't work, I wanted to make sure that it would actually work in real life like it did in my head. Spoiler alert. Noop. Sorta. A little. Enough to make me want to keep messing with it. But, no.

The design drawn large, but ultimately a sketch of a jacket laid flat on a table top... laid flat on a table top.

Then I duplicated it, cut it out, and cut through where the darts were in my drawing.

Then I messed around with the angle that the darts were overlapped onto themselves, and taped them. The result was the below.

The aim was to match the curvature of my back.

The problem is that the panel stops at my waist, which is where the thoracic curve turns into the lumbar curve... It's got an S-curve, but that's not what's supposed to be happening in that panel. So...

Fortunately, at this point, my wife stepped in. She's quite the sewing hobbyist with a background in theatre (not your typical tech company IT Director). She flushed all of that for me, and pointed me in the right direction. She started out by pulling out a pattern for a generic bodice. Obviously, it's a women's pattern, but backs is pretty much backs. She took my measurements, and printed me up a bodice pattern that was more or less my measurements, and I used it to make another paper template. I drew my darts onto this, and we played around with it.

Unfortunately, at this point in the process, I didn't really know what I was doing, where I was going, or how I was going to get there. This thread was not on my radar, and so documentation is unfortunately lacking. Fortunately, wife had a clue, and did her best to preserve my design while making the curve actually work. We organically found ourselves with a fairly classic set of darts as described here. Again, this is oriented toward female garments, but backs is backs.

Ultimately, we found ourselves here:

The pattern totally flat showing the location, angle, length, and width of the darts (zoom in for actual numbers):

Darts connected, but with the pattern laid flat. This makes it extra domey, because it sort of flattens out when it wraps around your torso:

From the side, still flat on the table:

From below, still flat on the table:

Here's another documentation lapse... We used scotch tape (the kind that releases easily) to tape the pattern to my shirt, and I moved all around. Arms in a full circle, touched my toes, rocked at my waist, etc. In the process of doing so, my shirt shifted around, so where the pattern initially sat exactly on the seams on my shoulders, for instance, it got a little twisted and my shirt bunched up. It makes the pattern look a little disheveled, but the fact that it's still attached using only "magic release" Scotch tape really shows how well this fits.

Straight on:

From the side:

The pattern at this point matches the curve of my back pretty much exactly. If it were the back panel of a jacket, it would be skin tight. This might actually not be the worst thing in the world, but I want some ease for layering and weight fluctuation.

What I learned from this exercise:

The goal was to figure out how darts work so that my design for Fivestar turns out like I want it to. Here's what I figured out:

- The darts need to point to the high spot. In this case, shoulder blades.

- If they're too wide/the angle is too large, the result will be a point instead of a dome.

- The angle of the dart affects the resulting curve, but it's sort of a complex relationship that's hard to explain, assuming I even understand it. The arch appears to form mostly perpendicular to the dart, so you want the darts oriented accordingly from the major seam adjacent. If you angle the dart like I did at the start, it just kinda does weird stuff. There's probably a way to mess with the angle to fine tune things a little more, but I'm not there yet.

- Longer darts make for tighter curves. Wider darts also make for tighter curves.

Again, just to stress, I do NOT know what I'm doing here. Playing it by ear. I believe the next step is to make the back panel larger for ease. Doing this at the seams/edges is pretty straight forward: bigger is bigger. If I add an inch to each side, that's the equivalent of 4" ease (I think) with 2" in the back panel and the same in the front panel. With the darts, that means I need to make them shorter, but I have to make them narrower proportionally. The pattern makers' ruler is clear with those 1/8" lines. I can incrementally shrink the darts proportionally using those lines. Setting the ruler down so that the 1/8" line is on top of the dart lines, and then trace the edge. Then just iterate.

Unfortunately, that means I need to cash in some social capital with wife. In a perfect world, I'd have a dress form. In this one, I just have me. It's hard to do my back since it's... you know... back there. Can't really reach or see what I'm doing. I'll hopefully get to this this weekend, and I'll try to document better going forward as I figure this out.

Also on the "next steps" list is the front equivalent of this back plate. That will hopefully be simpler.